500人にミーラス編集部が独自にアンケート※を実施。2024年に交際を開始した男女500人への結果をもとに「本当におすすめなアプリはどれなのか」ランキングを作りました。

マッチングアプリTop3

\\1位//

ウィズ

相性で探せる!

\2位/

ペアーズ

会員数No.1!

3位

タップル

恋活No.1!

マッチングアプリの利用に不安がある人は

こちらからチェックしてみてください!

- 調査期間:2024年3月1日〜3月31日

- 調査対象:対象のマッチングアプリを利用している、過去に利用実績がある方

- 調査回答数:500

- ランキング評価内容:実際に該当マッチングアプリを利用したことがある合計500人に対してインターネット上でのアンケート調査を実施。

マッチングアプリの選び方

【迷ったらチェック!】

マッチングアプリを選ぶときにチェックするポイントは2つです!

- 自分の利用目的&出会いたい年齢層で選ぶ。

- 料金が予算内かどうかチェック!

マッチングアプリは目的と年齢で選ぼう!

マッチングアプリによって利用者の年齢、利用目的、タイプはそれぞれ異なります。

自分の利用目的&出会いたい年齢層で選ぶことが大切。

以下の表を参考に、自分の目的と出会いたい年齢層を確認してみてください!

料金が予算内かどうかチェック!

マッチングアプリの料金体系には4つのタイプがあります!

- 女性のみ無料:課金した男性は出会いやすい

- 相手が有料会員なら無料:無料で真剣なユーザーと出会える

- 男性女性どちらも無料:人気が偏り、ライバルが多い

- 男性女性どちらも有料:男女ともに真剣なユーザーが集まる

有料アプリのメリットもありますが、できれば料金はおさえたいですよね。完全無料のアプリやうまく利用すれば無料で出会えるアプリもあります。

初心者はアプリの使い方に慣れていないので、「高い会員料を払ったのに出会えない」リスクを負わずに使用したいです。

女性で初心者の人はまず無料で使用できるアプリを使ってみるのがおすすめ!

マッチングアプリの相場は大体1ヶ月3000円~5000円です。

長期プランで割引が大きくなるアプリもあります。以下で詳しくみていきましょう。

人気アプリをピックアップして料金を比較しました。

| 利用目的 | アプリ | 1ヶ月 | 3ヶ月 | 6ヶ月 | 1年 |

|---|---|---|---|---|---|

| 恋活 婚活 | ウィズ (男性有料) | 3,600円 | 3,000円/月 | 2,217円/月 | 1,833円/月 |

| 恋活 婚活 | ペアーズ (男性有料) | 3,700円 | 3,300円/月 | 2,300円/月 | 1,650円/月 |

| 恋活 婚活 | タップル (男性有料) | 3,700円 | 3,200円/月 | 2,800円/月 | 2,234円/月 |

| 恋活 婚活 | オミアイ (男性有料) | 3,900円 | 3,267円/月 | 2,467円/月 | 1,900円/月 |

| 恋活 婚活 | ダイン (男性有料) | 6,500円/月 | 5,600円/月 | 4,800円/月 | 2,900円/月 |

| 遊び 恋活 | 東カレデート (男女同額) | 6,500円/月 | 4,933円/月 | 4,133円/月 | – |

婚活 恋活 再婚 | マリッシュ (男性) | 3,400円/月 | 2,933円/月 | 2,466円/月 | 1,650円/月 |

| 婚活 | ゼクシィ縁結び (男女同額) | 4,378円/月 | 3,960円/月 | 3,630円/月 | 2,640円/月 |

| 遊び その他 | ティンダー | 無料 | 無料 | 無料 | 無料 |

※ダインは23歳以上の男性の料金です。

決めきれないときは

大手3アプリをとりあえず入れよう

会員数の多い大手3アプリは”安全性×出会いやすさ”が抜群。

そのため選択肢が多くてどのマッチングアプリを使えばいいか迷ったときは、信頼性とユーザー数が豊富な大手3アプリを試してみるのが一番です。

\\1位//

ウィズ

相性で探せる!

\2位/

ペアーズ

会員数No.1!

3位

タップル

恋活No.1!

▼実際に使っているアプリをアンケートしてみた結果はこちら!

やはり、利用者の数は大手アプリが圧倒的で、ペアーズが1位でした!

| アプリ | 人数 |

|---|---|

| ペアーズ | 222人 |

| タップル | 125人 |

| ウィズ | 83人 |

| ティンダー | 69人 |

| オミアイ | 27人 |

| マッチ | 22人 |

| ゼクシィ縁結び | 20人 |

| マリッシュ | 18人 |

| ユーブライド | 11人 |

| ダイン | 10人 |

| 東カレデート | 10人 |

| ブライダルネット | 7人 |

| ポイボーイ | 3人 |

【2024年最新総合ランキング】

マッチングアプリのおすすめ

- 初心者でも使いやすいこと!

- 男女とも出会いやすいこと!

- 安全に使えるアプリなこと!

※料金は月額の金額

| アプリ名 | 評価 | 公式/詳細 | 目的 | 年齢 | 料金 | 編集部コメント |

|---|---|---|---|---|---|---|

\1位/  ウィズ | 100点 | 公式 詳細 口コミ | 恋活 婚活 | 20~ 40代 | 男性 3,600円 女性 無料 | ★相性の合う人と出会える 心理学に基づいたマッチング機能で相性のいい人が知れる! 若い世代や同年代のパートナーを探している人に最適です。 ★本命の相手探し 恋活から婚活まで使いやすい機能がたくさん。 マッチングアプリが初めての人から、将来の結婚相手探しまで誰にでもおすすめです! |

\2位/  ペアーズ | 98点 | 公式 詳細 | 恋活 婚活 | 20~ 30代 | 男性 3,700円 女性 無料 | ★国内利用率No.1 国内最大級の会員数を誇り、バランスの良いユーザー構成が魅力。 初心者から経験者まで幅広い層の人におすすめできます! |

\3位/  タップル | 97点 | 公式 詳細 | 恋活 婚活 | 10~ 30代 | 男性 3,700円 女性 無料 | ★本命の相手探し 恋活から婚活まで使いやすい機能がたくさん。 マッチングアプリが初めての人から、将来の結婚相手探しまで誰にでもおすすめです! |

4位  オミアイ | 89点 | 公式 詳細 | 婚活 恋活 | 20~ 30代 | 男性 3,900円 女性 無料 | ★20・30代の婚活に 900万人の会員とリーズナブルな料金が魅力。 30歳前後で真剣な出会いを求める人に向いています! |

5位  ダイン | 88点 | 公式 詳細 口コミ | 婚活 恋活 再婚 | 20~ 30代 | 男性 6,500円 女性 6,500円 | ★メッセージも不要ですぐ会える デートまでの手間が不要のアプリ! 直接会って相性を確かめたい人、 気軽にデートしたい人向け。 |

6位  ゼクシィ縁結び | 86点 | 公式 詳細 口コミ | 婚活 | 20~ 30代 | 男性 4,378円 女性 4,378円 | ★奥手な人も婚活できる コンシェルジュ機能付きでデートセッティング可能。 真剣な婚活を考える人におすすめです! |

7位  マリッシュ | 84点 | 公式 詳細 口コミ | 婚活 恋活 再婚 | 30~ 40代 | 男性 3,400円 女性 無料 | ★バツイチ/シンママにも 再婚者・シングル親を応援しているアプリ! 結婚願望が高い人・再婚考える人におすすめです。 |

8位  ユーブライド | 83点 | 公式 詳細 | 婚活 恋活 再婚 | 30~ 40代 | 男性 3,800円 女性 無料 | ★30代以上の真剣婚活 20年運営の信頼性高いアプリ。 結婚前提の真剣な出会いに最適! |

9位  マッチ・ ドットコム | 81点 | 公式 詳細 | 恋活 婚活 | 20~ 30代 | 男性 4,490円 女性 4,490円 | ★30・40代の真剣な出会い 充実した検索機能で海外の人とも出会いやすい! 異文化交流も楽しみたい人におすすめです! |

10位  ブライダルネット | 80点 | 公式 詳細 口コミ | 婚活 | 20~ 30代 | 男性 3,980円 女性 3,980円 | ★アプリ版結婚相談所 スピード感ある婚活を望むユーザーに特化しているのが魅力! 1年以内の結婚を目指す人にぴったりと言えます。 |

11位  ティンダー | 79点 | 公式 詳細 口コミ | 遊び その他 | 20~ 30代 | 男性 無料 女性 無料 | ★気軽なデートに 無料で気軽に世界中と繋がれます。 カジュアルな出会いと コスパを求める人に最適です! |

12位  東カレ デート | 74点 | 公式 詳細 口コミ | 遊び 恋活 | 20~ 30代 | 男性 6,500円 女性 6,500円 | ★ハイスペック男女向け 事前審査があり、ハイスペックなユーザーが多いのが特徴! 気軽にデートしたい人におすすめ。 |

13位  アンジュ | 72点 | 公式 詳細 | 恋活 | 30~ 50代 | 男性 3,500円 女性 無料 | ★30〜50代の大人向け 恋活から婚活まで! 中高年向けでAIマッチング支援が特徴。 落ち着いた関係を望む大人の男女に適しています! |

14位  ポイボーイ | 70点 | 公式 詳細 口コミ | 恋活 | 20~ 30代 | 男性 3,800円 女性 無料 | ★女の子が男性を選べる 若いユーザーが多く、女性からアプローチできるのが特徴。 積極的な女性・草食系男子向き! |

15位  イヴイヴ | 65点 | 公式 詳細 | 恋活 | 20~ 30代 | 男性 3,500円 女性 無料 | ★入会審査制で安心 入会審査ありなのにリーズナブル! 美男美女との出会いとコスパを両立したい人に最適。 |

「結婚を考えている」「真剣に婚活したい」という人は

婚活目的のアプリのまとめ記事もありますのでぜひ参考にしてみてください。

▼婚活目的でアプリを使いたい人はこちら

▼遊び相手や異性の友達がほしい人はこちら

【with(ウィズ)】

性格診断で価値観の合う相手が見つかる

- 独自の心理テストや性格診断を利用でき、自分と相性が合う相手を探せる

- 「好みカード」で相手の価値観や趣味を知って自分との共通点を見つけられる

- マッチングしたら、相手とのメッセージのやり取りがスムーズになるよう、様々な「トークアドバイス」が表示される

会員数800万人の心理学をもとにしたアプリ。相性診断による価値観マッチングができます。

ユーザーの年齢層が若いのも特徴です。

内面を細かく知るための機能が充実。自分と気が合う人に出会いやすいと評判です!

アンケートで分かった

実際にwith(ウィズ)を使っている人

アンケートで分かった実際にwith(ウィズ)を利用している人の男女の特徴や年齢、目的、口コミを紹介します!

with(ウィズ)についてもっと詳しく知りたい人はこちらもチェックしてください。

with(ウィズ)で出会える女性のイメージ・タイプ

ウィズで出会える女性のタイプとして最も多くあがったのが

品のある清楚系。次いでゆるふわ癒し系でした。

趣味では映画鑑賞が1位、次いで動物関連、音楽鑑賞など出会える女性のイメージにマッチした結果となりました。

おとなしめで女の子らしい子が多いのがウィズの特徴です。

with(ウィズ)で出会える男性のイメージ・タイプ

出会える男性のタイプで最も多くあがったのが、草食系。

営業職につく人が多く一般的なサラリーマンの男性が大半です。

趣味は、旅行とグルメが上位に来ており女性の趣味と合わせやすい男性と出会えます。

趣味が合いやすい男性と出会いたい

という人におすすめ!

with(ウィズ)利用者の年齢層

| 年齢 | 割合 |

|---|---|

| 20歳未満 | 1.2% |

| 20代前半 | 43.4% |

| 20代後半 | 33.7% |

| 30代前半 | 9.6% |

| 30代後半 | 4.8% |

| 40代前半 | 2.4% |

| 40代後半 | 2.4% |

| 50代以上 | 2.4% |

ウィズ利用者の年齢層は幅広いですが、20代前半が圧倒的に多いです。

with(ウィズ)を使い始めた目的

| アプリを使い始めた目的 | 割合 |

|---|---|

| 恋人探し(結婚意識せず) | 41.0% |

| 恋人探し(結婚前提) | 38.6% |

| 異性の友達探し | 7.2% |

| 結婚相手探し | 4.8% |

| 遊び相手探し(ワンナイト) | 3.6% |

| 暇つぶし | 2.4% |

| ハッキリした目的なし | 2.4% |

使い始めた目的は「恋人探し(結婚意識せず/結婚前提)」が上位にランクイン。

パートナーを求めて利用している人が多い傾向にあることが分かりました。

きちんと恋人を見つけたいという人に人気がありますね。

with(ウィズ)を実際に利用した人のリアルな口コミ評判は?

私と同じ趣味を持っていて、会話が弾むことが多かったです。

共通の話題で盛り上がることができ、お互いに笑顔で楽しい時間を過ごすことができました。

女性 20代後半 パート

相手は穏やかで気配りができるタイプで、会話も弾んで楽しい時間を過ごすことができました。

自分の意見をしっかり持ちつつも、相手の意見にも寛容であり、とても理解が深い人でした。

女性 30代後半 公務員

実際に自分のことをよく理解をしてくれそうな人を探していたので、出会うことが出来ました。

よく気を配ってくれる感じでもあり、とても良かったです。

男性 30代後半 フリーランス

Pairs(ペアーズ)

国内利用率No.1!初心者も出会いやすい

- 恋人ができるまでの平均期間が4ヶ月と短い。

- コミュニティ機能で趣味が合う人を探せる。

- 毎日約8,000人の会員登録を誇り、多くの会員から自分に合う人を探せる。

| 会員数 | 2000万人 |

| 多い年齢層 | 20代後半 |

| 月額料金 | 男性3,700円/無料 |

| 利用者の目的 | 恋活 婚活 |

| リンク | 公式 |

ペアーズは会員数2000万人で国内利用率No.1のマッチングアプリ!

外面・内面どちらかに偏らずユーザーのバランスが取れているのが特徴。男女共に会員数が多いため初心者におすすめ!

ペアーズは会員数が多いことが魅力。

会員数が多ければ多いほど、理想の相手に出会える可能性もアップします!

アンケートで分かった

実際にPairs(ペアーズ)を使っている人

アンケートで分かった実際にペアーズを利用している人の男女の特徴や年齢、目的、口コミを紹介します!

ペアーズについてもっと詳しく知りたい人はこちらもチェックしてください。

Pairs(ペアーズ)で出会える女性のイメージ・タイプ

ペアーズで出会えるタイプで最も多かったのは品のある癒し系。ゆるふわ癒し系が2位でした。

趣味ではグルメ関連が最も多く、次いで旅行関連が上位に来ていました。

音楽鑑賞や映画鑑賞に回答する人も多くいて色々な趣味の女性がいます。

可愛らしい女性とも品のある大人な女性とも出会いたい男性にぴったり!

Pairs(ペアーズ)で出会える男性のイメージ・タイプ

出会える男性のタイプで最も多かったのは普通のサラリーマンで、職業は事務職の人が最も多い結果となりました。

ハイスペックすぎる男性には少し緊張してしまうという女性におすすめです。

趣味はグルメ、旅行などアクティブなものが上位。

映画鑑賞や音楽鑑賞など落ち着いたものもランクインしているので、偏りはありません。

居心地のいい男性と出会いたい女性

におすすめ。

Pairs(ペアーズ)利用者の年齢層

| 年齢 | 割合 |

|---|---|

| 20歳未満 | 0.9% |

| 20代前半 | 18.9% |

| 20代後半 | 31.1% |

| 30代前半 | 23.4% |

| 30代後半 | 10.4% |

| 40代前半 | 6.8% |

| 40代後半 | 3.6% |

| 50代以上 | 5.0% |

ペアーズ利用者の年齢層は幅広いですが、20代後半~30代前半に集中している結果になりました。

Pairs(ペアーズ)を使い始めた目的

| アプリを使い始めた目的 | 割合 |

|---|---|

| 恋人探し(結婚意識せず) | 38.7% |

| 恋人探し(結婚前提) | 36.5% |

| 異性の友達探し | 9.9% |

| 結婚相手探し | 5.9% |

| 遊び相手探し(ワンナイト) | 4.5% |

| 暇つぶし | 3.2% |

| ハッキリした目的なし | 1.4% |

使い始めた目的は「恋人探し(結婚意識せず/結婚前提)」が上位に来ているため、全体としては「真剣に出会いたい」という人が多い結果になりました。

ペアーズは規模が国内最大級のアプリ。毎日約8,000人の会員登録を誇ります。

気軽な関係を求める人から真剣に出会いたい人まで色々な人がいることがわかりますね。

Pairs(ペアーズ)を実際に利用した人のリアルな口コミ評判は?

同年代の、営業マンのような爽やかな人と出会えました。

もっとチャラチャラした人が多いと思っていたので、驚きました。

女性 30代前半 事務職

自分自身大学生ということもあり、学生同士で出会うことが多かったです。

明るく活発的な方が多かったです。

男性 20代前半 学生

趣味や好みが自分と似た人に会うことができました。

食事の好みなども似ていて、デートをしたときも楽しく過ごせました。

女性 20代後半 営業職

Pairs(ペアーズ)について詳しく知りたい人はこちらもチェック!

tapple(タップル)

初めてのマッチングにおすすめなのは

タップルは、会員数1700万人で男女ともに若い世代の利用中心!

出会いのチャンスが多く、「おでかけ機能」で即日デートも可能です。すぐに出会いたいマッチングアプリ初心者におすすめ!

| 会員数 | 1700万人 |

| 多い年齢層 | 20代前半 |

| 月額料金 | 男性3,700円/無料 |

| 利用者の目的 | 恋活 婚活 |

| リンク | 公式 |

タップルは、今日や週末に会える相手をすぐ見つけられるのが魅力!

アンケートで分かった

実際にtapple(タップル)を使っている人

アンケートで分かった実際にtapple(タップル)を利用している人の男女の特徴や年齢、目的、口コミを紹介します!

tapple(タップル)についてもっと詳しく知りたい人はこちらもチェックしてください。

tapple(タップル)で出会える人の女性のイメージ・タイプ

タップルで出会える女性のタイプ1位はゆるふわ癒し系、次いで品のある清楚系。趣味はインドア系からアクティブなものまで幅広い結果に。

タップルは、大人な綺麗系よりやわらかい可愛い系の子が多いのが特徴です。

tapple(タップル)で出会える人の男性のイメージ・タイプ

タップルで出会える男性のタイプ1位は爽やか好青年系。次いで普通のサラリーマン。

趣味では音楽鑑賞が最も多く、アニメや漫画関連にも多く回答が寄せられていました。

タップルは、落ち着いた雰囲気の男性と出会いたいという人におすすめ!

tapple(タップル)利用者の年齢層

| 年齢 | 割合 |

|---|---|

| 20歳未満 | 4.0% |

| 20代前半 | 33.6% |

| 20代後半 | 26.4% |

| 30代前半 | 17.6% |

| 30代後半 | 11.2% |

| 40代前半 | 4.8% |

| 40代後半 | 1.6% |

| 50代以上 | 0.8% |

tapple(タップル)を使い始めた目的

| アプリを使い始めた目的 | 割合 |

|---|---|

| 恋人探し(結婚意識せず) | 40.0% |

| 恋人探し(結婚前提) | 25.6% |

| 異性の友達探し | 13.6% |

| 暇つぶし | 7.2% |

| ハッキリした目的なし | 6.4% |

| 遊び相手探し(ワンナイト) | 5.6% |

| 結婚相手探し | 1.6% |

タップル利用者の年齢層は20代が半分以上を占める結果になりました。

使い始めた目的は、結婚を意識している場合も結婚前提の場合も含めて「恋人探し」が上位にランクイン。

タップルは、結婚を意識せずとも恋人と出会いたい!という人に人気があります。

tapple(タップル)を実際に利用した人のリアルな口コミ評判は?

自分と真反対の社交的でアウトドアな人と出会いました。

デートの時にリードしてくれてすごくよかったです。

20代 女性 ショップ店員

自分が出会ったのは、職場にいても出会いが少ないという看護師の方。とても礼儀正しくて良い人でした。

30代 男性 事務職

趣味の合う人と出会うことができ、

趣味の話から発展し盛り上がりました。

20代 男性 営業職

- 趣味をきっかけに出会えるので、相手と価値観が合いやすい

- ニックネームで登録できる

- 困ったときは、24時間いつでもカスタマーサポートに相談可能

tapple(タップル)に関するよくある質問まとめ

タップルのよくある質問

- 知り合いにマッチングアプリを利用していることがバレないか心配です。

プロフィールの公開範囲を設定することは可能ですか? -

プライベートモードを利用すれば、自分がいいね!した相手・マッチングした相手にだけ自分のプロフィールが表示されます。

プライベートモードのメリット!- 料金は1ヶ月プランは男女ともに2,560円~。

- 不特定多数の相手から自分のプロフィールを隠したまま利用できる。

Omiai(オミアイ)

20〜30代の結婚を意識した”恋人作り”

オミアイは、会員900万人で検索システムが細かくて使いやすいのが特徴。

人気メンバー検索では、自分に合った見た目やタイプの女性を検索して探せるのが嬉しいポイント!

| 会員数 | 900万人 |

| 多い年齢層 | 20代後半 |

| 月額料金 | 男性3,900円/無料 |

| 利用者の目的 | 恋活 婚活 |

| リンク | 公式 |

他にもすぐに反応してくれるアクティブユーザーを検索で絞り込めます!

オミアイは検索機能が充実していますね。

アンケートで分かった

実際にOmiai(オミアイ)を使っている人

アンケートで分かった実際にOmiai(オミアイ)を利用している人の男女の特徴や年齢、目的、口コミを紹介します!

Omiai(オミアイ)についてもっと詳しく知りたい人はこちらもチェックしてください。

Omiai(オミアイ)で出会える女性のイメージ・タイプ

オミアイで出会える女性のイメージは、可愛い系、癒し系、清楚系に回答が偏りました。

派手なタイプよりは品のある女性が好みの男性にぴったりです。

旅行やグルメを趣味にする女性がほとんどでアクティブな女性と出会いたい男性にはぴったり。

オミアイは、品はあるけどアクティブな人が好みの男性におすすめ!

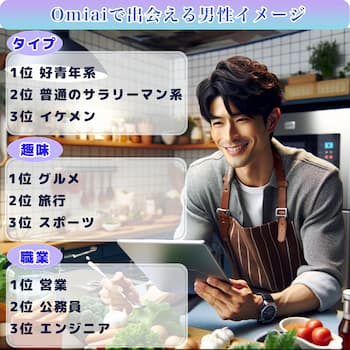

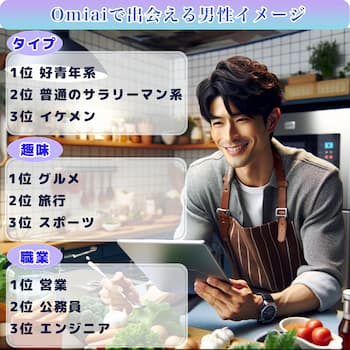

Omiai(オミアイ)で出会える男性のイメージ・タイプ

出会える男性のイメージは普通のサラリーマンと好青年系が同立1位でした。

職業は事務職や営業職の人が多いですが看護師や公務員、エンジニアもいて、とくに職業に偏りはありません。

趣味は旅行やグルメに回答が多く、映画鑑賞や音楽鑑賞などで情緒に浸るよりはアクティブに活動する人が多いです!

オミアイは、休みの日はアクティブに過ごす男性が多いのが特徴。

Omiai(オミアイ)利用者の年齢層

| 年齢 | 割合 |

|---|---|

| 20歳未満 | 0.0% |

| 20代前半 | 14.8% |

| 20代後半 | 51.9% |

| 30代前半 | 18.5% |

| 30代後半 | 7.4% |

| 40代前半 | 3.7% |

| 40代後半 | 3.7% |

| 50代以上 | 0.0% |

Omiai(オミアイ)を使い始めた目的

| アプリを使い始めた目的 | 割合 |

|---|---|

| 恋人探し(結婚意識せず) | 37.0% |

| 恋人探し(結婚前提) | 33.3% |

| 結婚相手探し | 25.9% |

| 遊び相手探し(ワンナイト) | 3.7% |

オミアイ利用者の年齢層は20代後半に集中している結果になりました。

使い始めた目的は「恋人探し」の次に「結婚相手探し」も上位にランクイン。

他のアプリと比べても「真剣に出会いたい」という人が多いことがわかりました。

オミアイは20代後半のユーザーが多い婚活アプリ。

そのため、結婚を意識する真剣度の高い人が多い傾向にありますね。

Omiai(オミアイ)を実際に利用した人のリアルな口コミ評判は?

私が元々ゲームが好きだったので、ゲーム好きの人でインドア気質の人を探していました。

探した結果、その通りの人と出会い、4回ほどデートして映画や食事に行ってみて楽しかったので告白して付き合うことが出来ました。

男性 20代後半 事務職

30代前半の長身で多趣味なタイプの男性で、お見合いのように価値観や仕事のこと色々なことをお話しすることかできました。

女性 30代前半 販売職

年上で少し天然っぽい印象を受けた人と出会い、デートもすることが出来ました。

女性 30代前半 営業職

- 実名ではなく、イニシャルやニックネームで利用できる

- お互いに「いいね!」をし合うと、マッチングが成立してメッセージ交換ができるようになる

- 不正なユーザーがいる場合に通報するシステムがあり、運営側が警告や強制退会などの対応をしてくれる

【Dine(ダイン)】

メッセージも不要。まずは会いたい人向け!

Dineは、レストランで会うことを前提としたデート直結型マッチングアプリ。

店決めから予約までアプリがサポートしてくれるのでデートの計画に負担がかかりません。

会うまでのやり取りがめんどくさいと感じている人におすすめです!

アンケートで分かった

実際にDine(ダイン)を使っている人

アンケートで分かった実際にDine(ダイン)を利用している人の男女の特徴や年齢、目的、口コミを紹介します!

Dine(ダイン)についてもっと詳しく知りたい人はこちらもチェックしてください。

Dine(ダイン)で出会える女性のイメージ・タイプ

ダインで出会える女性のイメージは、可愛い系、癒し系。

女性に癒されたい男性にぴったりです。

趣味は1位にグルメ、次いでスポーツ、アニメ・漫画でした。

男性の趣味にも合いそうな女性が多いのが特徴です。

ダインは、可愛い女性に癒されたい男性におすすめ!

Dine(ダイン)で出会える男性のイメージ・タイプ

出会える男性のイメージは草食系と好青年系が同立1位でした。

趣味は女性と同じくグルメと答えている人が多く、他にも旅行やスポーツなど活動的な人が多い結果になりました。

ダインは、休みの日は活動的な男性が多いのが特徴。

Dine(ダイン)利用者の年齢層

| 年齢 | 割合 |

|---|---|

| 20歳未満 | 3.6% |

| 20代前半 | 25.0% |

| 20代後半 | 25.0% |

| 30代前半 | 21.4% |

| 30代後半 | 14.3% |

| 40代前半 | 7.1% |

| 4Dine(ダイン)0代後半 | 3.6% |

| 50代以上 | 0.0% |

Dine(ダイン)を使い始めた目的

| アプリを使い始めた目的 | 割合 |

|---|---|

| 恋人探し(結婚意識せず) | 42.9% |

| 恋人探し(結婚前提) | 25.0% |

| 暇つぶし | 10.7% |

| 遊び相手探し(ワンナイト) | 7.1% |

| ハッキリした目的なし | 7.1% |

| 異性の友達探し | 3.6% |

| 結婚相手探し | 3.6% |

ダイン利用者の年齢層は20代~30代前半がほとんどを占める結果になりました。

使い始めた目的は「恋人探し(結婚意識せず)」が上位にランクイン。

他にも「暇つぶし」、や「遊び相手探し(ワンナイト)」も多く、結婚は意識せずに利用する人が多い傾向があることが分かりました。

気軽に会いたい人におすすめですね。

Dine(ダイン)を実際に利用した人のリアルな口コミ評判は?

自分は、オンラインゲームを一緒にできる友達を探すのに使っていました。

実際に5~6人の人達と連絡先を交換してゲームなしで遊ぶことが凄く増えました。

男性 30代前半 エンジニア職

いろんな趣味をもっていてたくさんの事を知っている人に出会えました。

私の趣味が旅行なのでお互い行ってよかった所や美味しかったものの共有をするのがすごく楽しかったです。

女性 30代前半 パート

お食事を奢ってくれる男性が多く、大手企業の会社員で収入が安定していて、穏やかな人が多かったです。

あんまりガツガツした人がいなくて、初回はお食事だけで解散の人が多かったのが好印象でした。

女性 20代後半 事務職

【ゼクシィ縁結び】

奥手な人も安心!真剣な婚活

ゼクシィ縁結びは、株式会社リクルートが運営している婚活マッチングアプリ!

男女の月額料金が同額!そのため男女ともに結婚に対して真剣な人が集まっていると評判です。

アプリ側が自分の価値観と合う相手を毎日4人紹介してくれるのが嬉しいポイントですね!

ゼクシィ縁結びで出会える人のイメージ・タイプ

出会える女性のタイプで最も多かったのは清楚系と癒し系でした。

ギャル系や肉食系に回答した人はいないので、全体的に派手すぎない清純な女性が多いです!

音楽鑑賞、グルメ、旅行、動物など色々な趣味の人がいましたがスポーツやゲーム、お酒など一般的に男性に多い趣味をもつ人は見られませんでした。

ゼクシィ縁結びは、派手すぎない女性と出会いたい人におすすめです。

出会える男性のタイプで最も多かったのは普通のサラリーマン。

職業はエンジニアが最も多く、次いで営業と公務員が同立2位、事務職が3位でした。

アンケートでは学生もおらず、一般的な働く現役世代の男性が多いです。

男性の趣味で最も多かったのは旅行。特徴的なのは他のアプリで上位にあがるグルメを趣味にする人がいなかったところ。

ゼクシィ縁結びは、食べること以外にたくさん趣味のある女性は気の合う男性と出会いやすいです。

ゼクシィ縁結びを実際に利用した人の

リアルな年齢・目的は?

ゼクシィ縁結び利用者の年齢層

| 年齢 | 割合 |

|---|---|

| 20歳未満 | 0.0% |

| 20代前半 | 0.0% |

| 20代後半 | 35.0% |

| 30代前半 | 30.0% |

| 30代後半 | 25.0% |

| 40代前半 | 0.0% |

| 40代後半 | 5.0% |

| 50代以上 | 5.0% |

ゼクシィ縁結びを使い始めた目的

| アプリを使い始めた目的 | 割合 |

|---|---|

| 恋人探し(結婚前提) | 35.0% |

| 結婚相手探し | 30.0% |

| 恋人探し(結婚意識せず) | 25.0% |

| 異性の友達探し | 5.0% |

| 暇つぶし | 5.0% |

ゼクシィ縁結び利用者の年齢層は20代後半から30代後半に集中している結果になりました。

使い始めた目的は「恋人探し(結婚前提)」、「結婚相手探し」が上位にランクイン。

結婚相手を探すために利用している人が多い傾向にあります。

ゼクシィ縁結びは婚活を主な目的としたアプリ。

本気で結婚相手を探している人が多いということが分かりました。

ゼクシィ縁結びを実際に利用した人のリアルな口コミ評判は?

他のマッチングアプリに比べると真面目な人が多いイメージがあります。

真剣に結婚相手や交際相手を探していたり、あまり女性慣れしてないような感じの方が多かったです。

女性 30代前半 医療専門職

ゼクシィ縁結びは本気の方向けと聞いていた通り、出会いを求めているのではなく結婚相手を求めている方と出会えました。

自分もそうだったので、本気度が同じレベルの女性とマッチングすることが出来ました。

男性 20代後半 事務職

年齢層がかなり高めなので自分のタイプの年齢の方には出会えなかったのですが、優しくて気前のいい方とは会えました。

あとは結構物静かで話さない人が多かったです。

女性 20代前半 パート

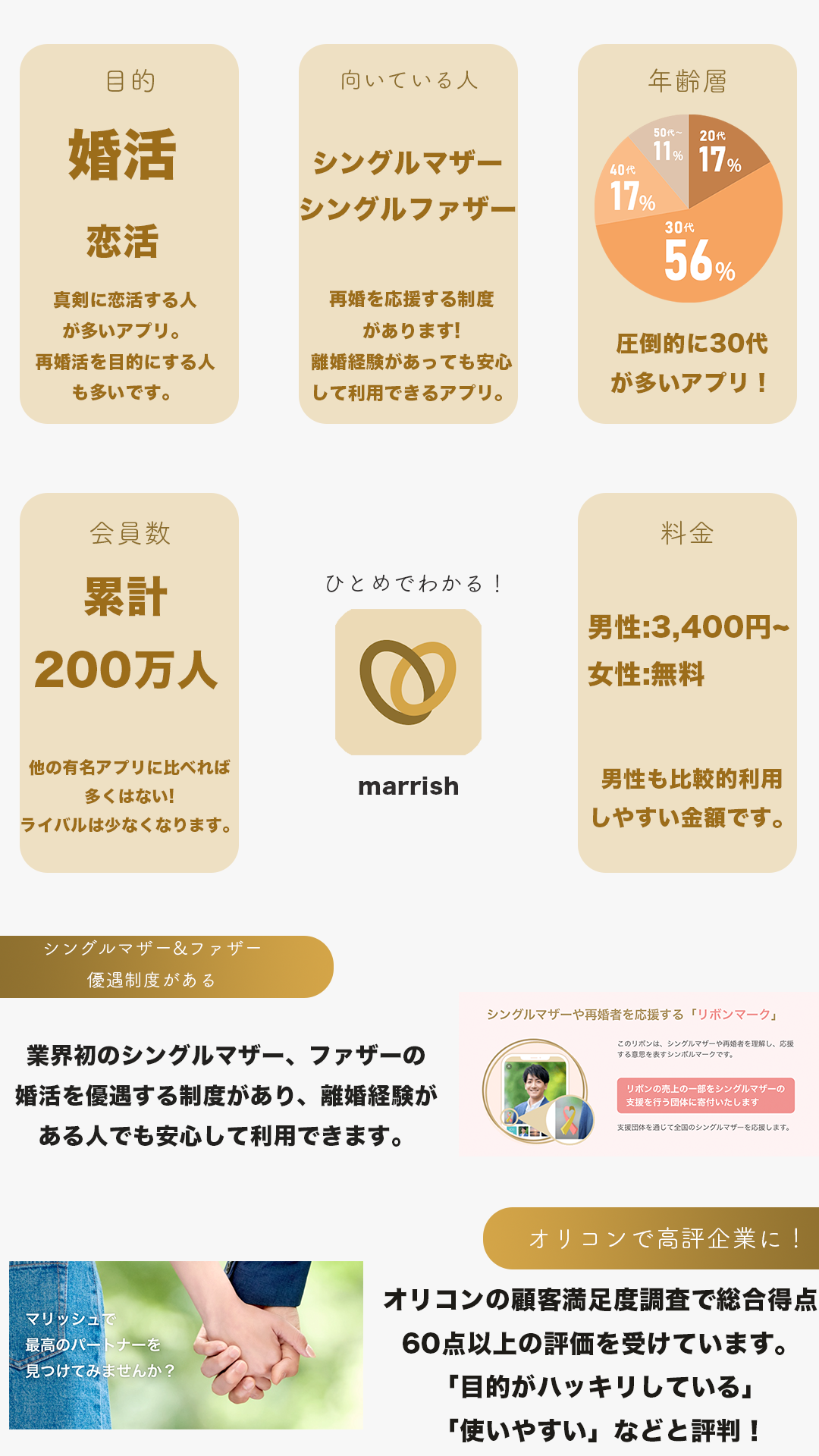

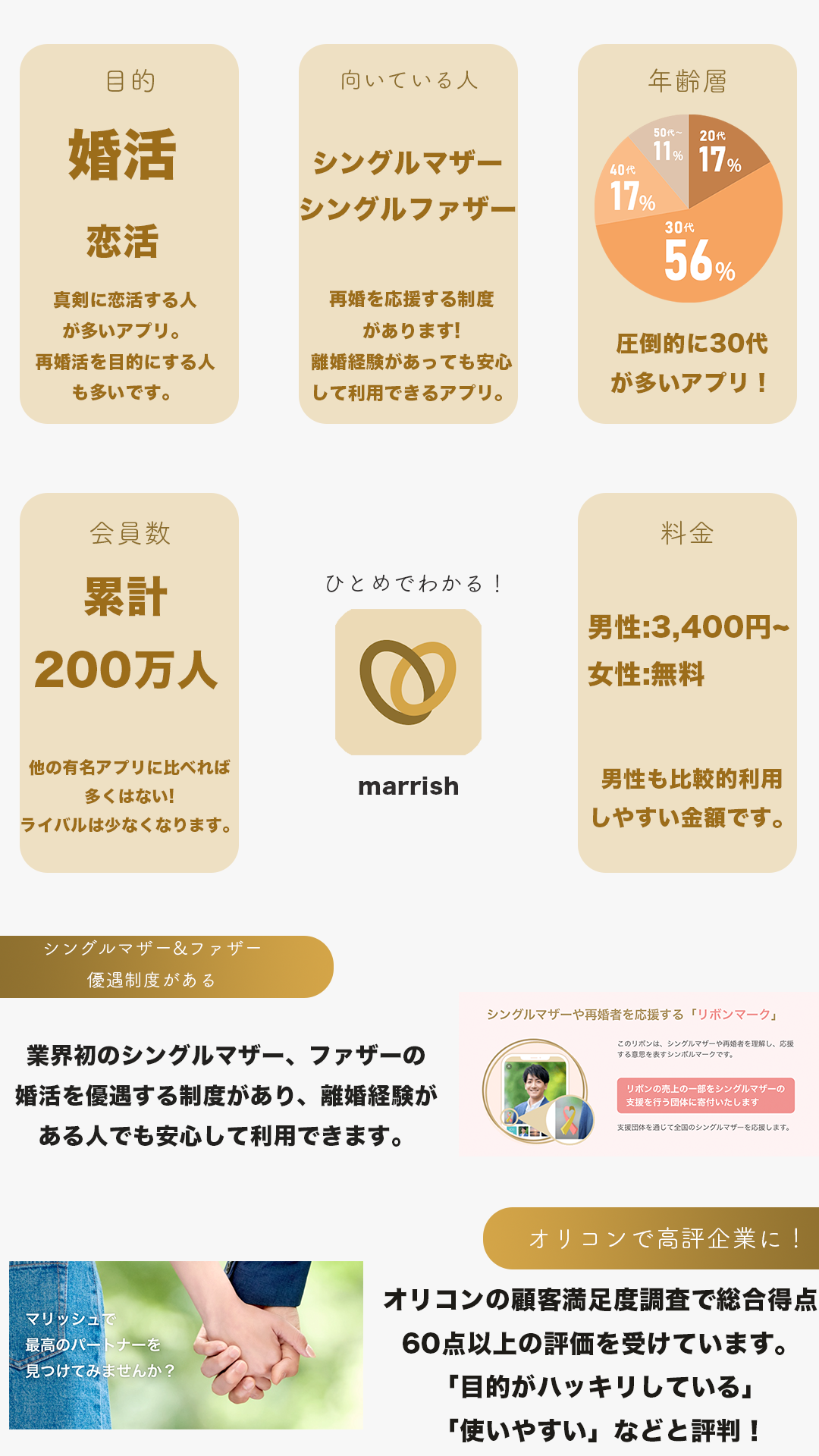

【マリッシュ】

アラフォー・バツイチ・シンママ向きの

会員数200万人のマリッシュは、再婚者の婚活を応援するマッチングアプリ!

再婚者&シングルマザー&シングルファザーの優遇制度があるのが特徴。結婚願望が高いユーザーも多く、本気で再婚したい人におすすめ!

マリッシュは、アプリ内で通話ができ、実際に会ったときの「思っていた印象となんだか違う」を防ぐことができるのが魅力!

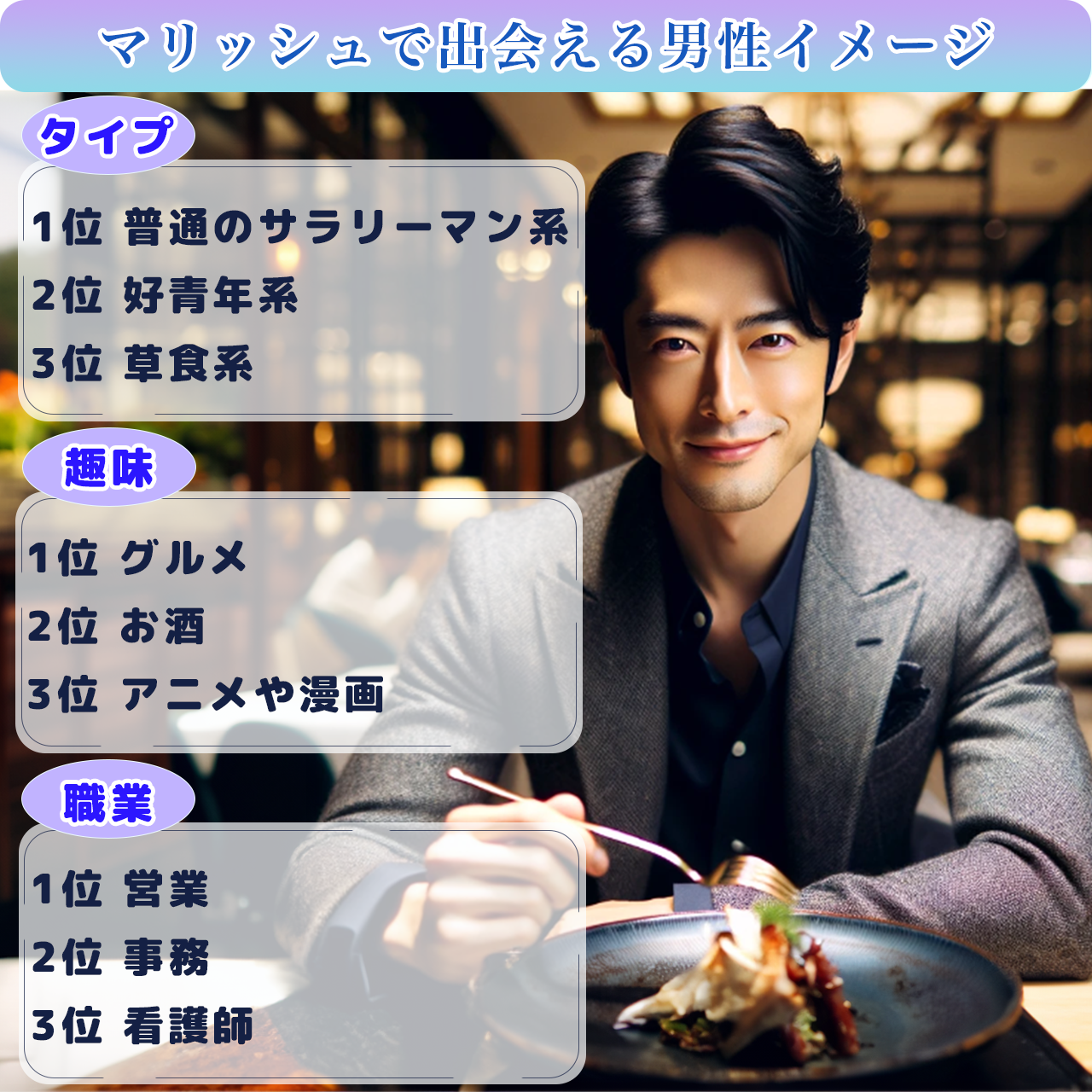

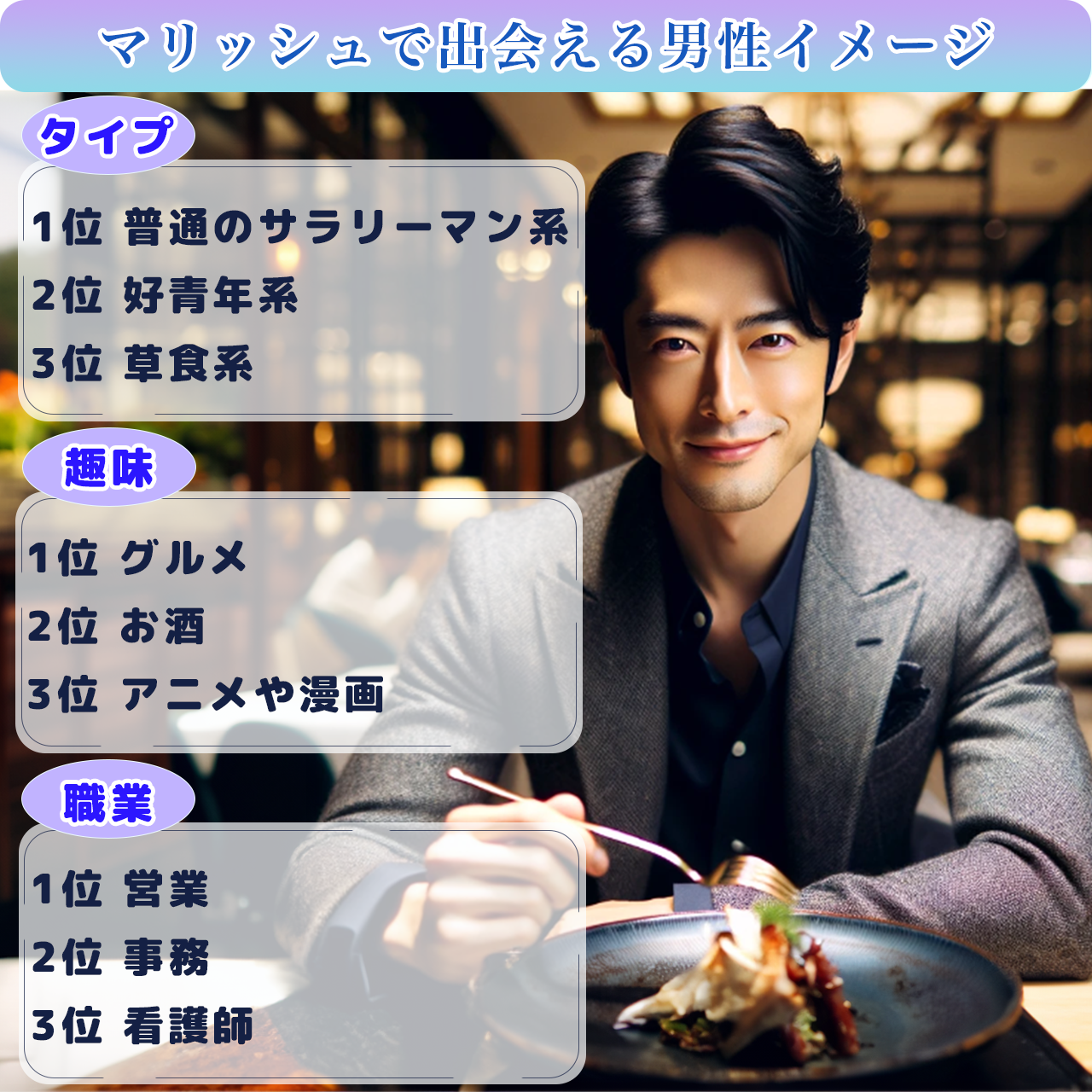

マリッシュで出会える人のイメージ・タイプ

マリッシュで出会える女性のタイプ1位は可愛い系、2位は癒し系でした。

趣味はグルメや音楽鑑賞など女の子らしい趣味が上がりました。

マリッシュは、女の子らしい可愛い系の子が多いのが特徴です。

マリッシュで出会える男性のタイプ1位は普通のサラリーマン系、2位は好青年系でした。

趣味はグルメやお酒など。

食事に行くのが趣味の会社員と出会うことができそうです。

マリッシュは、食事に行くことが趣味の女性にピッタリです。

マリッシュを実際に利用した人の

リアルな年齢・目的は?

マリッシュ利用者の年齢層

| 年齢 | 割合 |

|---|---|

| 20歳未満 | 0.0% |

| 20代前半 | 16.7% |

| 20代後半 | 0.0% |

| 30代前半 | 27.8% |

| 30代後半 | 27.8% |

| 40代前半 | 16.7% |

| 40代後半 | 0.0% |

| 50代以上 | 11.1% |

マリッシュを使い始めた目的

| アプリを使い始めた目的 | 割合 |

|---|---|

| 恋人探し(結婚前提) | 38.9% |

| 恋人探し(結婚意識せず) | 22.2% |

| 結婚相手探し | 16.7% |

| 遊び相手探し(ワンナイト) | 16.7% |

| 異性の友達探し | 5.6% |

マリッシュ利用者の年齢層は30代前半~40代前半が多く、年齢層高めの結果になりました。

使い始めた目的は「恋人探し(結婚前提)」が上位にランクイン。

「結婚前提でお付き合いしたい」という人が多いという結果になりました。

マリッシュは再婚活を応援するアプリ。

そのため年齢層は高めですね。

マリッシュを実際に利用した人のリアルな口コミ評判は?

マリッシュを実際に使った人のネットの口コミ

同じ世代のわりと落ち着いた方と出会いたかったので、マリッシュを使ってみました。

趣味が同じや似ている方で、話が合ったりLINEが途切れず続いたり、こちらが頑張りすぎなくても楽しく穏やかに過ごせる方と出会うことが出来ました。

男性 30代後半 エンジニア職

優しい雰囲気で、私が話すのがあまり得意ではないので、そんな私でも受け入れて下さる器の大きい人と出会うことが出来ました。

女性 30代前半 パート

付き合いたい人の譲れない条件として、背の高さが180センチくらいある人としていたのですが、181センチの男性と出会うことが出来ました。

実際に会った時も、初めて会う緊張があまりなくて自然と会話も弾み「もう、この人しかいない!」と思いました。

女性 30代前半 事務職

- 再婚者やシンママとシンパパへ、ポイント増量などの優遇プログラムが充実している

- 声プロフ機能があり、自分の声を録音してアピール可能

- マリッシュ内で音声通話を利用できるので、実際に会う前に相手の雰囲気を確かめることができる

【ユーブライド】

30代以上の真剣な婚活に。

累計会員数は220万人!運営年数は20年で信頼性の高いユーブライド!

30~40代のユーザーが多く、結婚前提の交際がしやすいのが特徴。婚活を目的にマッチングアプリを使用する人におすすめ!

| 会員数 | 累計220万人 |

| 多い年齢層 | 30代、40代 |

| 月額料金 | 男性/女性4,300円 |

| 利用者の目的 | 恋活 婚活 |

| リンク | 公式 |

ユーブライドは、真剣に結婚を考えているユーザーが多いのが魅力!

ユーブライドで出会える人のイメージ・タイプ

ユーブライドで出会える女性のタイプ1位は可愛い系、次いで癒し系でした。

趣味はグルメや旅行、スポーツなど男性にも合わせやすい趣味があがりました。

ユーブライドは、癒される可愛い系の子が多いのが特徴です。

ユーブライドで出会える男性のタイプ1位は好青年系でした。

趣味はグルメやゲームなどインドアの人もアウトドア人も合わせられる趣味があがりました。

ユーブライドは、インドアもアウトドアもいける男性が多いのが特徴です。

ユーブライドを実際に利用した人の

リアルな年齢・目的は?

ユーブライド利用者の年齢層

| 年齢 | 割合 |

|---|---|

| 20歳未満 | 0.0% |

| 20代前半 | 27.3% |

| 20代後半 | 0.0% |

| 30代前半 | 36.4% |

| 30代後半 | 18.2% |

| 40代前半 | 9.1% |

| 40代後半 | 9.1% |

| 50代以上 | 2.4% |

ユーブライドを使い始めた目的

| アプリを使い始めた目的 | 割合 |

|---|---|

| 恋人探し(結婚前提) | 36.4% |

| 恋人探し(結婚意識せず) | 27.3% |

| 結婚相手探し | 27.3% |

| 遊び相手探し(ワンナイト) | 9.1% |

ユーブライド利用者の年齢層は30代~が多いですが、20代前半も比較的多く、若い年代にも人気であることが分かりました。

使い始めた目的は「恋人探し(結婚前提)」が上位にランクイン。

結婚相手探しも上位にきているため、「結婚を意識して出会いを探している」人が多い結果になりました。

ユーブライドは運営年数が長く、信頼性の高いアプリ。

そのため真剣な出会いを探す人が多いですね。

ユーブライドを実際に利用した人のリアルな口コミ評判は?

理想のタイプの女性で無事デートが出来ました。

女性の性格はサバサバした性格で物事をハッキリ言う人でした。

男性 40代後半 営業職

初めてマッチングして初めて会った人が今の夫です。

何度かデートを重ねるうちに思ったより気さくで意外とアウトドアなことが分かり、スムーズに距離を縮めることができました。

女性 30代前半 パート

初めて会った日から笑顔の絶えない一緒にいて凄く癒される人でした。

趣味が同じだったので会話も弾み初めて会った気がしないくらいストレスがなく落ちつくタイプの方でした。

男性 30代前半 エンジニア職

【マッチ・ドットコム】

女性も有料! 30~40代の真剣な出会い

アメリカ発祥のマッチ。利用者は世界中に1500万人で、独身者向けの恋活・婚活マッチングアプリです。

LGBTの人への対応もしているので、性別や国に限らず幅広く恋愛したい人にも人気!

| 会員数 | 200万人 |

| 多い年齢層 | 30代 |

| 月額料金 | 男性/女性4,490円 |

| 利用者の目的 | 恋活 婚活 |

| リンク | 公式 |

多種多様なユーザーから自分好みの相手を探したい人におすすめです。

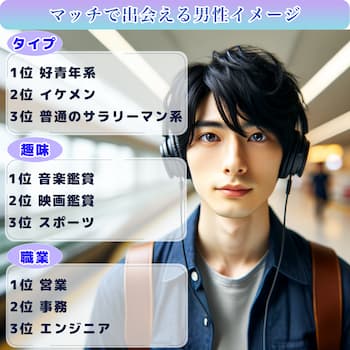

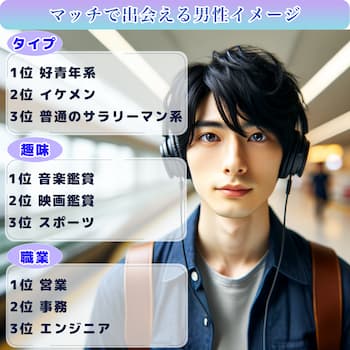

マッチで出会える人のイメージ・タイプ

マッチで出会える女性のタイプ1位は癒し系、2位はギャル系がランクイン。

可愛い系からガツガツ系まで色んなタイプの女性がいます。

趣味はグルメやお酒、旅行が多かったです。お酒が好きな男性にぴったりかもしれません。

マッチは可愛い系かギャル系までいろんなタイプの女性がいるのが特徴です。

マッチで出会える男性のタイプ1位は好青年系、2位はなんとイケメンでした。

趣味は音楽鑑賞や映画鑑賞などのインドア系からスポーツなどのアウトドア系まで、幅広く趣味を持つ人が多かったです。

マッチは、好青年なイケメン好きおすすめです。

マッチを実際に利用した人の

リアルな年齢・目的は?

マッチ利用者の年齢層

| 年齢 | 割合 |

|---|---|

| 20歳未満 | 0.0% |

| 20代前半 | 40.9% |

| 20代後半 | 9.1% |

| 30代後半 | 22.7% |

| 30代後半 | 18.2% |

| 40代前半 | 4.5% |

| 40代後半 | 4.5% |

| 50代以上 | 0.0% |

マッチを使い始めた目的

| アプリを使い始めた目的 | 割合 |

|---|---|

| 恋人探し(結婚前提) | 31.8% |

| 遊び相手探し(ワンナイト) | 22.7% |

| 恋人探し(結婚意識せず) | 18.2% |

| 暇つぶし | 13.6% |

| ハッキリした目的なし | 9.1% |

| 異性の友達探し | 4.5% |

マッチ利用者の年齢層は20代前半が多く次いで30代後半と、幅広い年代が利用している結果になりました。

使い始めた目的は、結婚前提の「恋人探し」を目的にしている人もいれば、「遊び相手探し」を目的にしている人も多かったです。

マッチは、本気の恋愛をするより遊びたい!という人にもおすすめ!

マッチを実際に利用した人のリアルな口コミ評判は?

ギャップがある人もいればない人もいましたが、アプリをやっていなかったら出会えなかったタイプの人とも会えたため、とても楽しかったです。

女性 20代前半 事務職

普通の社会人の女性の方と出会いました。

特にアプリで連絡を取り合ったときと印象は変わらなく、楽しいデートとなりました。

お酒を飲みに行ったのですが、終始話は盛り上がりとても楽しい時間を過ごすことができました。

男性 30代後半 営業職

年上で綺麗な方がタイプですが、その通りの方と出会うことが出来ました。

顔立ちは今までお付き合いした方の中でダントツに一番でした。

趣味もスポーツ好きで私も同じだったため、すぐに意気投合しました。

男性 30代後半 事務職

【ブライダルネット】

まるでアプリ版の結婚相談所!

ブライダルネットは、会員数200万人で本気で婚活をする人が多いマッチングアプリ!

すぐに結婚をしたいスピード感を求めている人におすすめ!

真剣な出会いを求めている男女におすすめです!

ブライダルネットで出会える人のイメージ・タイプ

ブライダルネットで出会える女性のタイプ1位は清楚系。

趣味は旅行や音楽鑑賞、映画鑑賞などが上位にランクインしました。

ブライダルネットは、おとなしめの清楚系の子が多いのが特徴です。

ブライダルネットで出会える男性のタイプ1位は草食系、次いで普通のサラリーマン!

趣味では旅行が最も多く、音楽鑑賞にも多く回答が寄せられていました。

ブライダルネットは、おとなしめの男性が多いのが特徴です。

ブライダルネットを実際に利用した人の

リアルな年齢・目的は?

ブライダルネット利用者の年齢層

| 年齢 | 割合 |

|---|---|

| 20歳未満 | 0.0% |

| 20代前半 | 14.3% |

| 20代後半 | 33.6% |

| 30代前半 | 14.3% |

| 30代後半 | 14.3% |

| 40代前半 | 14.3% |

| 40代後半 | 14.3% |

| 50代以上 | 0.8% |

ブライダルネットを使い始めた目的

| アプリを使い始めた目的 | 割合 |

|---|---|

| 結婚相手探し | 42.9% |

| 恋人探し(結婚前提) | 28.6% |

| 恋人探し(結婚意識せず) | 28.6% |

ブライダルネット利用者の年齢層は20代後半を中心に年齢層高めの結果になりました。

ブライダルネットを使い始めた目的は「結婚相手探し」と答えた人がほぼ半数を占めていました。

ブライダルネットは、結婚相手といち早く出会いたい!という人に人気があります。

ブライダルネットを実際に利用した人のリアルな口コミ評判は?

ブライダルネット利用者の年齢層

容姿が自身の理想の方と出会うことが出来ました。

性格も優しく思い遣りのある人で人間性も好みのタイプの女性でした。

デートに江の島ドライブに行き、実際に付き合うことが出来ました。

男性 40代後半 事務職

映画鑑賞が趣味の気が合う人出会うことが出来ました。

デートは出来ませんでしたが、共通の話題で盛り上がることは出来ました。

女性 20代前半 フリーター

自分自身との趣味や、仕事が合う方とデートをすることが出来ました。

実際に食事に行くことも出来ました。

男性 30代後半 エンジニア職

【ティンダー】

気軽にデートできる!Z世代に人気なアプリ

Tinderは誰でも無料で使えるマッチングアプリとして、若者を中心に人気を博しています。

多くの国で利用されているため、外国人/海外に住んでいる人と繋がれると評判です。

気軽に出会いを求める遊び目的の人におすすめのアプリですよ。

ティンダーで出会える人のイメージ・タイプ

ティンダーで出会える女性のタイプで最も多かったのは可愛い系でした。

ユーザーの年齢層が若いだけあって若々しい印象の女性が多いです!

幼い印象の女性だけでなく美人系も2位にランクインしているので色んなタイプを求める男性が使用できます。

お酒を趣味にする女性が最も多かったのでお酒好きの男性にはぴったりです。

男性とも趣味の合う女性が多く、異性の友達探しにもぴったりです。

出会える男性のタイプはイケメンが最も多く、次いで普通のサラリーマンが多い結果になりました。

ほかのアプリより色んなタイプに回答が分散しているので出会える男性のタイプはとくに限られていません。

気軽に始められて、会員数も多いアプリなので出会えるタイプも幅広いです!

職業は圧倒的に営業の人が多く、趣味もスポーツが最も多いのでスポーツマンのような強い男性と出会いたい人はぜひタップルを試してみましょう!

とにかくいろんなタイプの男性と出会いたい!という女性におすすめです。

ティンダーを実際に利用した人の

リアルな年齢・目的は?

ティンダー利用者の年齢層

| 年齢 | 割合 |

|---|---|

| 20歳未満 | 10.1% |

| 20代前半 | 42.0% |

| 20代後半 | 26.1% |

| 30代前半 | 10.1% |

| 30代後半 | 4.3% |

| 40代前半 | 4.3% |

| 40代後半 | 2.9% |

| 50代以上 | 0.0% |

ティンダーを使い始めた目的

| アプリを使い始めた目的 | 割合 |

|---|---|

| 遊び相手探し(ワンナイト) | 30.4% |

| 恋人探し(結婚意識せず) | 21.7% |

| 暇つぶし | 20.3% |

| ハッキリした目的なし | 11.6% |

| 異性の友達探し | 10.1% |

| 恋人探し(結婚前提) | 4,3% |

| その他 | 1.4% |

ティンダー利用者の年齢層は20代前半が圧倒的に多く、若い年代が利用しているということが分かりました。

使い始めた目的は遊び相手探し(ワンナイト)が多い結果になりました。

やはり「気軽に会いたい」という人が多いという結果になりました。

ティンダーは位置情報で近くにいる人とすぐ出会えるアプリ。

そのため気軽に会いたい人が使うイメージということがわかりますね。

ティンダーを実際に利用した人のリアルな口コミ評判は?

ティンダーを実際に使った人のネットの口コミ

自分の見た目がタイプな人と出会えてうれしい気持ちになりました。

新しい価値観を知れる機会になりました。

男性 20代後半 エンジニア職

草食系の人、お兄ちゃんタイプの人と出会うことが出来ました。

自分の気の合う人と出会い、色々な話をして、色々な場所に行き、楽しい思い出を作ることができました。

女性 20代後半 看護師

ティンダーで出会って実際に付き合い、もうすぐ2年半になります。

最初、ティンダーは遊びたい人が使ってるイメージが多くて、私自身も遊び半分で使用していたので、素敵な出会いがあると思っていませんでした。

女性 20代前半 学生

【東カレデート】

高収入イケメン/綺麗な女性とのデートは

”ワンランク上の出会いを”をキャッチコピーにしている会員数3万人の東カレデート。

学歴や年収の厳しい基準をクリアした人のみが会員となれる完全審査制でハイスペックな男女のユーザーばかり。

審査が厳しく、美男美女も多いため自分に自信のある人におすすめのマッチングアプリです。

厳重な審査を通ったハイスペックな異性と出会うことができますよ。

東カレデートで出会える人のイメージ・タイプ

東カレデートで出会える女性のタイプで多かったのは癒し系、可愛い系でした。

趣味は、お酒を趣味にする女性が最も多かったです。

職業はフリーランスと事務が多く、デートをするときは時間を合わせやすいかと思います。

可愛い女性とお酒を飲みたい男性にぴったりです。

出会える男性のタイプはハイスぺが最も多い結果になりました。高学歴・高収入な男性と出会える可能性が高いです。

趣味はお酒やグルメがあがりました。グルメ通な女性にはぴったりです。

職業は公務員や医者などやはりレベルが高い職業についている男性が多かったです。

ハイスぺ男性と美味しいお酒やご飯を食べたい!という女性におすすめです。

東カレデートを実際に利用した人の

リアルな年齢・目的は?

東カレデート利用者の年齢層

| 年齢 | 割合 |

|---|---|

| 20歳未満 | 0.0% |

| 20代前半 | 15.4% |

| 20代後半 | 30.8% |

| 30代前半 | 7.7% |

| 30代後半 | 15.4% |

| 40代前半 | 23.1% |

| 40代後半 | 7.7% |

| 50代以上 | 0.0% |

東カレデートを使い始めた目的

| アプリを使い始めた目的 | 割合 |

|---|---|

| 恋人探し(結婚意識せず) | 30.8% |

| 異性の友達探し | 23.1% |

| 恋人探し(結婚前提) | 15.4% |

| 結婚相手探し | 15.4% |

| 暇つぶし | 7.7% |

| ハッキリした目的なし | 7.7% |

東カレデート利用者の年齢層は20代後半が一番多かったです。次いで40代前半が多く、男性利用者の年齢層が高いことからこのような結果になりました。

使い始めた目的は、恋人探し(結婚意識せず)が一番多く、次いで多かったのが意外にも異性の友達探しでした。

友達探し目的に利用することもアリですよ。

東カレデートは他のアプリと比べて登録するための審査が厳しいアプリ。

ハイスぺな異性を探すにはちょうど良いです。

東カレデート利用者のクチコミ評価

東カレデートを実際に使った人のネットの口コミ

アラフォーの草食系男性と出会いました。

控えめな感じではありましたが、誠実な方でした。

女性 20代前半 パート

出会った方はしっかりと自立した女性で人間性も良く印象が良かったです。

素敵な女性とデートが出来て楽しく充実した時間を過ごせたので、東カレデートを利用して良かったと思いました。

男性 40代後半 営業職

自分のタイプだと感じる人とは出会えておりませんが、年齢層や趣味などが近しい方や仕事の業界が全く異なる方と何度かお会いして食事をしたりすることで自分の視野が広がった気がします。

女性 20代後半 事務職

【アンジュ】

30〜50代の大人な恋活・婚活に!

アンジュは、中高年の利用が多いマッチングアプリ!

すぐに出会うための検索機能が充実しており、空いた時間にサクッと異性を探すことが可能です!

| 会員数 | 60万人 |

| 多い年齢層 | 30代~50代 |

| 月額料金 | 男性3,800円/無料 |

| 利用者の目的 | 恋活 婚活 |

| リンク | 公式 |

身分証明書による年齢確認、24時間365日の監視などセキュリティ面にも気を遣っていて安心です。

アンジュで出会える人のイメージ・タイプ

アンジュで出会える女性のタイプで多かったのは美人系でした。

美人好きな男性にはぴったりです。

趣味は、グルメを趣味にする女性が最も多かったです。

大人で美人な雰囲気が漂う女性に会いたい男性にぴったりです。

出会える男性のタイプは好青年系が最も多い結果になりました。

次いでイケメンは2位でした。男女共に顔面が整っている人に出会うことが出来そうです。

趣味は旅行やグルメなどアウトドア派な女性にぴったりです。

好青年な男性にサポートされたい!という女性におすすめです。

アンジュを実際に利用した人の

リアルな年齢・目的は?

アンジュ利用者の年齢層

| 年齢 | 割合 |

|---|---|

| 20歳未満 | 2.9% |

| 20代前半 | 0.0% |

| 20代前半 | 20.0% |

| 30代前半 | 37.1% |

| 30代後半 | 14.3% |

| 40代前半 | 14.3% |

| 40代後半 | 8.6% |

| 50代以上 | 2.9% |

アンジュを使い始めた目的

| アプリを使い始めた目的 | 割合 |

|---|---|

| 恋人探し(結婚前提) | 31.4% |

| 恋人探し(結婚意識せず) | 28.6% |

| 遊び相手探し(ワンナイト) | 14.3% |

| 異性の友達探し | 14.3% |

| 結婚相手探し | 5.7% |

アンジュ利用者の年齢層は30代前半が一番多かったです。利用者の年齢層が高いことが分かりました。

使い始めた目的は結婚前提の恋人探しが一番多かったですが、遊び相手や異性の友達探しで使っている人もいることから、それぞれの目的をもって利用している人が多いことが分かりました。

アンジュは中高年代に向けた恋活アプリ。他のアプリと比べて年齢層が高いです。

アンジュを実際に利用した人のリアルな口コミ評判は?

アンジュを実際に使った人のネットの口コミ

アンジュのメリットは、独自機能「好みマッチ」で相性のいい相手と出会えることです。

メッセージをする前の段階で相手と自分の相性がある程度わかったので、いい感じの人と会えてよかったです。

女性 40代前半 営業職

消防士という職業柄、職場に女性がいなくて、合コンみたいな場も苦手だったので、出会いがなく軽い気持ちでアプリを始めました。

始めて3ヶ月ごろにいいねをくれた女性と会って、去年結婚することが出来ました。

男性 30代前半 消防士

誠実そうで年収1000万の方を探していましたが、実際出会えて食事までできました。

また、お話も楽しくできた方でした。

女性 40代前半 事務職

【ポイボーイ】

女の子が男性を選べる新感覚アプリ

ポイボーイは、会員数110万人越えの女性が男性を選ぶスタイルのマッチングアプリ。自分からアプローチするのが苦手な男性や自分好みの男性を選びたい女性はポイボーイがおすすめ!

容姿だけでなく、趣味や共通点を見つけてアプローチする機能もついているので安心して恋活できます!

ポイボーイで出会える人のイメージ・タイプ

ポイボーイで出会える女性のタイプで多かったのは肉食系でした。

ガツガツ積極的に来てほしい男性にはぴったりです。

趣味は、お酒を趣味にする女性が最も多かったです。

積極的な肉食系女子に会いたい男性にぴったりです。

出会える男性のタイプはイケメンが最も多い結果になりました。

趣味はスポーツが一番多くあがりました。

イケメンでスポーツ好きの女性にはぴったりです。

見た目にこだわりたいという女性におすすめです。

ポイボーイを実際に利用した人の

リアルな年齢・目的は?

ポイボーイ利用者の年齢層

| 年齢 | 割合 |

|---|---|

| 20歳未満 | 0.0% |

| 20代前半 | 33.3% |

| 20代後半 | 0.0% |

| 30代前半 | 0.0% |

| 30代後半 | 33.3% |

| 40代前半 | 33.3% |

| 40代後半 | 0.0% |

| 50代以上 | 0.0% |

ポイボーイを使い始めた目的

| アプリを使い始めた目的 | 割合 |

|---|---|

| 恋人探し(結婚意識せず) | 33.3% |

| 遊び相手探し(ワンナイト) | 33.3% |

| 異性の友達探し | 33.3% |

ポイボーイ利用者の年齢層は20代前半から40代前半まで幅広い結果になりました。

使い始めた目的は、恋人探しの割合が多かったものの、遊び相手や異性の友達探しも多かったため真剣度は低いことが分かりました。

気軽に恋活をしたいという方にはちょうど良いです。

ポイボーイを実際に利用した人のリアルな口コミ評判は?

ポイボーイを実際に使った人のネットの口コミ

誠実な方が多く、彼女を探している人もいれば、純粋に異性の友人を探している人もいました。

特にがつがつした感じはなく、自然と連絡も取りながら気が合う部分を探し、スムーズにデートに繋がりました。

女性 20代前半 パート

清潔感がある感じの方だった。体型も、中肉中背の方でした。

ごく普通の方でした。

女性 40代前半 事務職

自分の好みのタイプと出会うことが出来ました。

良い感じになった人と私から誘って映画を見に行きました。

男性 30代後半 営業職

【イヴイヴ】

入会審査制で安心の20~30代向けアプリ

会員数200万人のイヴイヴは恋活向けのマッチングアプリ!入会に審査が必要で美男美女が多いと言われています。比較的リーズナブルでコストパフォーマンスを求める人におすすめ!

| 会員数 | 200万人 |

| 多い年齢層 | 20代前半 |

| 月額料金 | 男性3,500円/女性0円 |

| 利用者の目的 | 恋活 婚活 |

| リンク | 公式 |

外見が整った異性が多いという口コミも多く寄せられていますよ。

イヴイヴで出会える人のイメージ・タイプ

イヴイヴで出会える女性のタイプで多かったのは可愛い系、癒し系でした。

可愛い女性に癒されたい男性にはぴったりです。

趣味は、グルメや映画鑑賞を趣味にする女性が最も多かったです。

可愛い系の女性に会いたい男性にぴったりです。

出会える男性のタイプは好青年系が多い結果になりました。

趣味は、グルメと映画鑑賞など趣味も合わせやすい結果になりました。

趣味の合う男性とデートがしたいという女性におすすめです。

イヴイヴを実際に利用した人の

リアルな年齢・目的は?

イヴイヴ利用者の年齢層

| 年齢 | 割合 |

|---|---|

| 20歳未満 | 0.0% |

| 20代前半 | 9.1% |

| 20代後半 | 24.2% |

| 30代前半 | 33.3% |

| 30代後半 | 12.1% |

| 40代前半 | 12.1% |

| 40代後半 | 9.1% |

| 50代以上 | 0.0% |

イヴイヴを使い始めた目的

| アプリを使い始めた目的 | 割合 |

|---|---|

| 恋人探し(結婚意識せず) | 36.4% |

| 異性の友達探し | 24.2% |

| 恋人探し(結婚前提) | 21.2% |

| 遊び相手探し(ワンナイト) | 9.1% |

| 暇つぶし | 6.1% |

| 結婚相手探し | 3.0% |

編集部によるアンケート調査では、イヴイヴ利用者の年齢層は20代後半~30代前半が多いという結果に。

使い始めた目的1位は、結婚を意識しない恋人探し。次いで多かったのが異性の友達探し。

コスパが良く手軽に使えるアプリなので、気軽に会いたい人におすすめです。

イヴイヴは他のアプリと比べてコスパが良いので、若い年代にも人気なのかもしれません。

イヴイヴを実際に利用した人のリアルな口コミ評判は?

イヴイヴを実際に使った人のネットの口コミ

私と同じ趣味を持っていて、会話が弾むことが多かったです。

共通の話題で盛り上がることができ、お互いに笑顔で楽しい時間を過ごすことができました。

女性 20代後半 パート

相手は穏やかで気配りができるタイプで、会話も弾んで楽しい時間を過ごすことができました。

自分の意見をしっかり持ちつつも、相手の意見にも寛容であり、とても理解が深い人でした。

女性 30代後半 公務員

実際に自分のことをよく理解をしてくれそうな人を探していたので、出会うことが出来ました。

よく気を配ってくれる感じでもあり、とても良かったです。

男性 30代後半 フリーランス

アンケート調査からわかった!

【目的別】おすすめのマッチングアプリ

ここからは、目的別におすすめのマッチングアプリを紹介していきます。

恋活におすすめな

マッチングアプリ3選

おすすめ恋活アプリ3つ

\\1位//

ウィズ

相性で探せる!

\2位/

ペアーズ

会員数No.1!

3位

タップル

今日会える!

▼「アプリの利用目的はなんですか?」に対する

アンケート回答結果はこちら!

| アプリを使い始めた目的 | ウィズ | ペアーズ | タップル |

| 恋人探し(結婚前提) | 38.6% | 36.5% | 40.0% |

| 恋人探し(結婚意識せず) | 41.0% | 38.7% | 25.6% |

| 結婚相手探し | 4.8% | 5.9% | 1.60% |

| 遊び相手探し | 3.6% | 4.5% | 5.60% |

| 異性の友達探し | 7.2% | 9.9% | 13.60% |

| 暇つぶし | 2.4% | 3.2% | 7.20% |

| ハッキリした目的なし | 2.4% | 1.4% | 6.40% |

| その他 | 0.0% | 0.00% | 0.00% |

| 公式サイト 詳細ボタン | 公式 詳細 | 公式 詳細 | 公式 詳細 |

ウィズ、ペアーズ、タップルは

恋人探しの割合が圧倒的多数!

▼「実際にお付き合いしましたか?」に対する

アンケート回答結果はこちら!

ウィズは半数以上がお付き合いしているという結果に!

価値観マッチングができることも理由の1つと言えそうですね。

婚活におすすめな

マッチングアプリ3選

おすすめ婚活アプリ3つ

\\1位//

オミアイ

\2位/

ゼクシィ縁結び

3位

マリッシュ

▼「アプリの利用目的はなんですか?」に対する

アンケート回答結果はこちら!

| アプリを使い始めた目的 | オミアイ | ゼクシィ縁結び | マリッシュ |

| 恋人探し (結婚前提) | 33.30% | 35.0% | 38.9% |

| 恋人探し (結婚意識せず) | 37.00% | 25.0% | 22.2% |

| 結婚相手探し | 25.90% | 30.0% | 16.7% |

| 遊び相手探し | 3.70% | 0.0% | 16.7% |

| 異性の友達探し | 0.00% | 5.0% | 5.6% |

| 暇つぶし | 0.00% | 5.0% | 0.00% |

| ハッキリした目的なし | 0.00% | 0.0% | 0.00% |

| その他 | 0.0% | 0.0% | 0.00% |

| 公式サイト 詳細ボタン | 公式 詳細 | 公式 詳細 | 公式 詳細 |

オミアイ、ゼクシィ縁結び、マリッシュは

恋人探し(結婚前提)・

結婚相手探しの利用が多数!

▼「実際に結婚しましたか?」に対する

アンケート回答結果はこちら!

オミアイは結婚を意識しない恋人探しの利用が多いにも関わらず、

結婚した人の割合がNo.1です!

気軽な出会いにおすすめな

マッチングアプリ3選

気軽に出会えるアプリ3つ

\\1位//

ティンダー

\2位/

東カレデート

3位

ダイン

▼「アプリの利用目的はなんですか?」に対する

アンケート回答結果はこちら!

| アプリを使い始めた目的 | ティンダー | 東カレデート | ダイン |

| 恋人探し(結婚前提) | 4.3% | 20.0% | 40.0% |

| 恋人探し(結婚意識せず) | 21.7% | 20.0% | 30.0% |

| 結婚相手探し | 0.0% | 20.0% | 10.0% |

| 遊び相手探し(ワンナイト) | 30.4% | 0.0% | 10.0% |

| 異性の友達探し | 10.1% | 20.0% | 0.00% |

| 暇つぶし | 20.3% | 10.0% | 10.00% |

| ハッキリした目的なし | 11.6% | 10.0% | 0.00% |

| その他 | 0.0% | 0.00% | 0.00% |

| 公式サイト 詳細ボタン | 公式 詳細 | 公式 詳細 | 公式 詳細 |

ティンダーは、遊び相手探しや暇つぶしでの利用が特徴的でした。

東カレデート/ダインは、主に恋人や結婚相手を探す人が多いことがわかります。

デート向けアプリでも、アプリによって利用者の目的に違いがありますね。

▼「アプリでデートした人数は何人ですか?」に対する

アンケート回答結果はこちら!

| デートした人数 | ティンダー | 東カレデート | ダイン |

| 1人 | 21.7% | 20.0% | 20.0% |

| 2人~3人 | 39.1% | 70.0% | 30.0% |

| 4~5人 | 11.5% | 0.0% | 0.0% |

| 6~10人 | 7.2% | 0.0% | 30.0% |

| 11~15人 | 2.9% | 10.0% | 0.0% |

| 16以上 | 10.1% | 0.0% | 10.0% |

| 公式サイト 詳細ボタン | 公式 詳細 | 公式 詳細 | 公式 詳細 |

無料で出会いたい人におすすめなマッチングアプリ

無料期間があったり、ミッションをクリアしたり招待コードを使ったりして無料で利用できるアプリもありますよ。

| アプリ名 | 会員数 | 料金(※) | 年齢層 | 目的 |

|---|---|---|---|---|

ティンダー(Tinder) 無料登録 | 非公開 | 男性:無料 女性:無料 | 20代 | 出会い |

タップル(tapple) 無料登録 | 累計1,700万人 | 男性:月額3,700円 女性:無料 外部サービス登録で 最大2ヶ月間無料 | 20代 | 出会い 恋活 |

ウィズ(with) 無料登録 | 累計700万人 | 男性:月額3,600円 女性:無料 21歳以下に限り 外部サービス登録で 最大3ヶ月間無料 | 20代 30代 | 恋活 婚活 |

マリッシュ(marrish) 無料登録 | 累計600万人 | 男性:月額3,400円 女性:無料 外部サービス登録 ログインボーナスで無料 | 30代 40代 | 婚活 |

ユーブライド(youbride) 無料登録 | 累計240万人 | 男性:月額2,400円 女性:月額2,400円 相手が有料会員である間無料 | 30代 40代 | 婚活 |

ダイン(Dine) 無料登録 | 非公開 | 22歳以下:月額3,900円 23歳以上:月額6,500円 招待コード入力で1週間無料 | 20代 30代 | 出会い 恋活 |

オミアイ(Omiai) 無料登録 | 累計900万人 | 男性:月額1,900円 女性:無料 外部サービス登録で 最大1ヶ月間無料 | 30代 | 恋活 婚活 |

東カレデート 無料登録 | 非公開 | 男性:月額6,500円 女性:月額6,500円 招待コード入力で1週間無料 | 20代 30代 40代 | 出会い 恋活 |

完全無料のマッチングアプリはTinder(ティンダー)だけ!

結論、会員数が多く、完全無料のマッチングアプリはTinder(ティンダー)のみ!

| 会員数 | 非公開 |

| 男性料金 | 無料 |

| 女性料金 | 無料 |

| 年齢層 | 20代 |

| 目的 | 出会い |

Tinder(ティンダー)は安全?利用者の特徴は?

ティンダーは、20代の若い年齢層の会員が多いマッチングアプリ。

「半径2キロ以内」のように、指定した距離で相手を探すことができるので、行動範囲が似ている人とマッチングすることができます。

異性だけではなく同性ともマッチング可能で、友人や飲み仲間、趣味仲間探しで利用している人も多いです。

真剣な婚活目的で利用している人は少なく、フランクな関係になるユーザーがほとんどです。

初めから結婚前提で相手を探している場合は、マッチングが難しいかもしれません。

気軽に遊べるような出会いを求めている人や、中心部だけではなく地方や海外でも出会いたい人が多く利用しています。

- カジュアルな出会いを求めている

- 完全無料でマッチングアプリを使いたい

- 行動範囲が似ている人に出会いたい

- 結婚前提の真剣な出会いがほしい

- 30代以上の落ち着いた年齢層の人に出会いたい

- メッセージのやりとりが苦手

Tinder(ティンダー)は無料でどこまで使える?

通常、男性は有料なことが多いマッチングアプリですが、ティンダーは男女共に無料で利用できるアプリ。

プロフィールの登録やマッチング、気になる相手に送るLIKE、メッセージの送受信と、出会うまでの幅広い内容が無料で使えます。

もちろん課金することで、マッチングをサポートする機能を使うことも可能です。

| 無料で使える機能 | ・プロフィールの登録やマッチング ・気になる相手に送るLIKE ・メッセージの送受信 |

| オプション料金で使える機能 | ・LIKE送信回数無制限 ・プロフィールの優先表示 ・位置情報の設定変更 |

ティンダーは無料で使える範囲で十分出会えます。

有料でアピールするよりも、相手と楽しくやり取りできるテクニックを身につけましょう。

【年齢別】おすすめのマッチングアプリを紹介

ここからは、年齢別におすすめのマッチングアプリを紹介していきます。

マッチングアプリは、自分と同年代の人、同じ目的の人が多いものを選ぶことがポイント!

大学生におすすめのマッチングアプリ

大学生の中でも利用目的・出会いたい年齢層は様々ですよね。

ここでは「同世代と出会いたい」「年上とデートしてみたい」「たくさん会って遊びたい」大学生向けに、

料金が相場3000~4000円以内の人気アプリをまとめました!

大学生におすすめのマッチングアプリはこちら!

| アプリ | どんな大学生におすすめか! | 料金 | リンク |

タップル | ★同世代と気軽にデートしたい大学生 18〜24歳までの学生が半数以上! お出かけ機能で今日会える相手を探しやすいです。 | 男性:3700円/月 女性:無料 | 公式 詳細 口コミ |

ウィズ | ★同世代~20代前半と価値観でマッチング したい大学生 圧倒的に20代が多いのが特徴!価値観でマッチングできる機能が豊富。 同年代のパートナー&内面から合う人を見つけたい学生に最適です。 | 男性:3600円/月 女性:無料 | 公式 詳細 口コミ |

ペアーズ | ★検索機能で理想の相手に出会いたい大学生 国内最大級の会員数で検索機能が充実しているのが特徴。 コミュニティ機能を使って大学名と年齢で絞り込めます!理想の相手を見つけてしっかり恋愛したい大学生におすすめ。 | 男性:3700円/月 女性:無料 | 公式 詳細 口コミ |

オミアイ | ★年上としっかり恋愛したい大学生 20代後半~30代の人中心。年上と真剣に結婚や恋愛をした人におすすめです。 | 男性:3900円/月 女性:無料 | 公式 詳細 口コミ |

ティンダー | ★遊び/デートしたい大学生 真剣な交際というより、遊びや友達探しで利用する若者におすすめ。無料でたくさん出会いたい大学生にぴったりです。 | 男性:無料 女性:無料 | 公式 詳細 口コミ |

20代におすすめのマッチングアプリ

ここでは「本気で婚活したい」「ゆるく婚活したい」「まずは恋人を探したい」「たくさん会って遊びたい」20代向けに、料金が無料~5000円以内の人気アプリをまとめました!

| アプリ | どんな20代におすすめか! | 料金 | リンク |

ゼクシィ 縁結び | 【本気で婚活したい20代におすすめ】 ★1年以内に結婚前提の交際相手を見つけたい人にピッタリ 男女同額なので婚活に真剣な男女が集まっています。 利用者は20~30代が多数。大手が運営していてセキュリティサポートがしっかりしているので安心。 | 男性:4,378円 女性:4,378円 | 公式 詳細 |

オミアイ | 【ゆる〜く婚活をしたい20代】 ★同じ趣味や職業の人と真剣交際したい人ピッタリ 結婚を意識した恋活に人気のアプリ。20~30代の若い年齢層が多いのが特徴。気になるキーワードで相手を絞れる検索機能のも魅力。運営の監視体制がしっかりしていてセキュリティ面でも安心。 | 男性:3,900円 女性:無料 | 公式 詳細 |

ペアーズ | 【まずは恋人を探したい】 ★理想の相手を見つけて恋愛したい人にピッタリ 国内最大級の会員数で検索機能が充実。コミュニティ機能を使って年齢で絞り込めます。20代の恋活で迷ったらとりあえずペアーズを入れておけば安心! | 男性:3700円/月 女性:無料 | 公式 詳細 |

ティンダー | 【会いたい! 遊びたい!】 ★無料でたくさん出会いたい人にピッタリ 真剣な交際というより、遊びや友達探しで利用する若者におすすめ。無料でたくさん出会いたい20代にぴったりです。 | 男性:無料 女性:無料 | 公式 詳細 |

オミアイとペアーズは

「ゆる〜く婚活をしたい人など婚活まではいかない、、

でも、将来を見据えた真剣な相手と出会いたい!」

という人にもおすすめ!

上記以外にも、

・ハイスペック男女とデートしたい人なら東カレデート

・外国人と出会いたいならマッチ・ドットコム

など、出会いたい相手や目的に合わせてアプリを選びましょう!

▼20代男女に実際に使っているアプリをアンケートしてみた結果はこちら!

| 利用経験のあるアプリ | 人数 |

|---|---|

| ペアーズ | 111人 |

| タップル | 75人 |

| ウィズ | 64人 |

| ティンダー | 47人 |

| オミアイ | 18人 |

| マッチ | 11人 |

| ゼクシィ縁結び | 7人 |

| ダイン | 5人 |

| 東カレデート | 5人 |

| ブライダルネット | 3人 |

| マリッシュ | 3人 |

| ユーブライド | 3人 |

| ポイボーイ | 1人 |

詳しく解説した記事もあるので、チェックしてください!

30代におすすめのマッチングアプリ

実は、30代の5人に1人がマッチングアプリの使用経験あり!

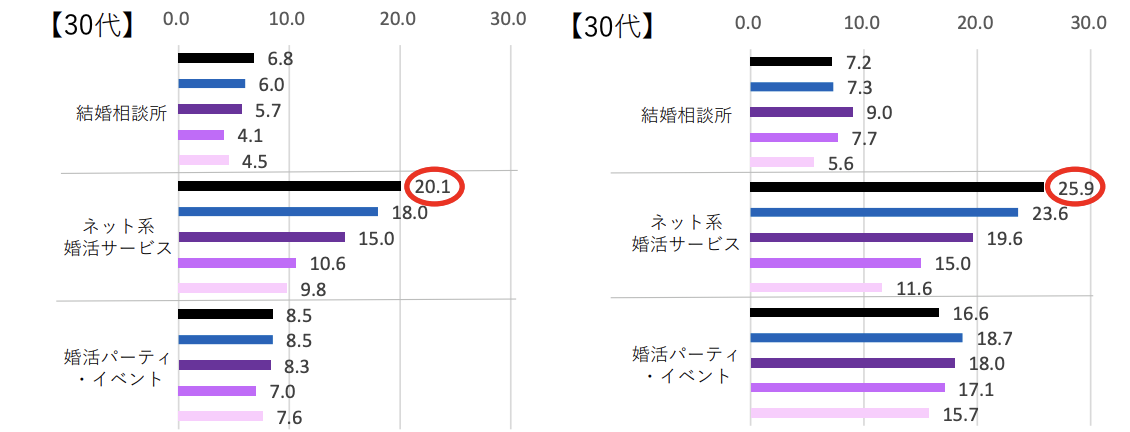

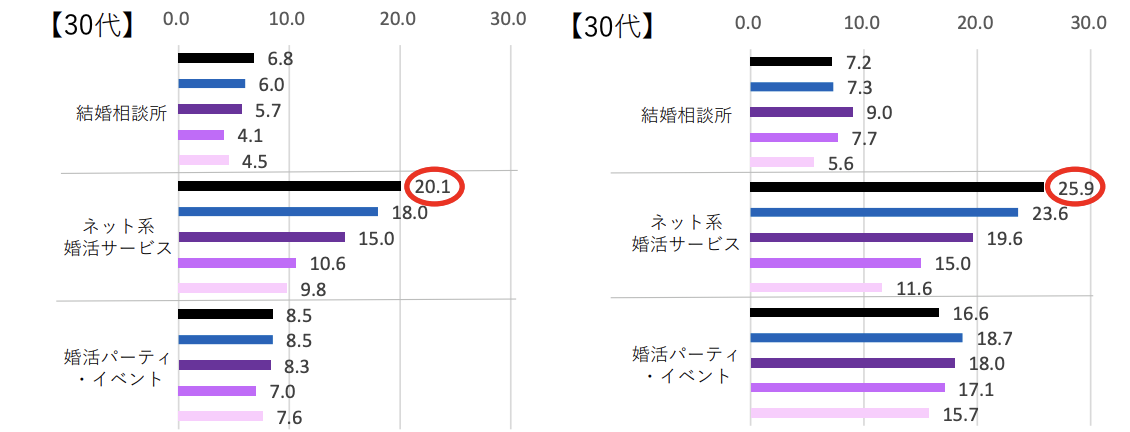

リクルートブライダル総研の「婚活実態調査2021」のデータ(左:男性,右:女性)によると、

30代のうち5人に1人以上がマッチングアプリの利用経験ありだとわかります。

マッチングアプリで出会いを求めているのは、主に20代の若者ばかりではありません!

30代の方々こそ、マッチングアプリを利用することで素敵な出会いを見つけるチャンスが豊富!

ここから、30代の出会いにおすすめなマッチングアプリを詳しく解説していきます!

同じ30代でも前半か後半かで、出会いやすいおすすめのアプリは異なります。

30代前半におすすめのマッチングアプリは、Pairs、ブライダルネット、Dineの3つ。

20代から30代の利用者が多いアプリなので、年下との出会いも年上との出会いも期待できます。

30代後半におすすめのマッチングアプリは、ゼクシィ縁結び、Match、youbrideの3つ。

男女ともに有料のアプリが多く、真剣な出会いや恋活・婚活を楽しめるものが多いです。

▼30代男女に実際に使っているアプリをアンケートしてみた結果はこちら!

| 利用経験のあるアプリ | 人数 |

|---|---|

| ペアーズ | 75人 |

| タップル | 36人 |

| ウィズ | 12人 |

| ゼクシィ縁結び | 11人 |

| マリッシュ | 10人 |

| ティンダー | 10人 |

| マッチ | 9人 |

| オミアイ | 7人 |

| ユーブライド | 6人 |

| ダイン | 5人 |

| 東カレデート | 2人 |

| ブライダルネット | 2人 |

| ポイボーイ | 1人 |

詳しく解説した記事もあるので、チェックしてください!

40代におすすめのマッチングアプリ

40代にとくにおすすめのマッチングアプリは、Match、marrish、youbrideの3つ。

30〜40代の利用者が多く、同年代や年下との出会いが期待できます。

▼40代男女に実際に使っているアプリをアンケートしてみた結果はこちら!

| 利用経験のあるアプリ | 人数 |

|---|---|

| ペアーズ | 23人 |

| タップル | 8人 |

| ティンダー | 5人 |

| ウィズ | 4人 |

| マリッシュ | 3人 |

| 東カレデート | 3人 |

| オミアイ | 2人 |

| ブライダルネット | 2人 |

| ユーブライド | 2人 |

| マッチ | 2人 |

| ゼクシィ縁結び | 1人 |

| ポイボーイ | 1人 |

| ダイン | 0 |

詳しく解説した記事もあるので、チェックしてください!

50代〜シニアにおすすめのマッチングアプリ

50代におすすめのマッチングアプリは、Match、marrish、アンジュ。

どれも40代以上がメインユーザーのアプリで、中には再婚活を応援してくれるものも。

50代でも出会えるものばかりなので、チャレンジしてみてください。

▼50代男女に実際に使っているアプリをアンケートしてみた結果はこちら!

| 利用経験のあるアプリ | 人数 |

|---|---|

| ペアーズ | 11人 |

| ウィズ | 2人 |

| マリッシュ | 2人 |

| タップル | 1人 |

| ゼクシィ縁結び | 1人 |

| ティンダー | 0 |

| オミアイ | 0 |

| マッチ | 0 |

| ダイン | 0 |

| 東カレデート | 0 |

| ブライダルネット | 0 |

| ユーブライド | 0 |

| ポイボーイ | 0 |

詳しく解説した記事もあるので、チェックしてください!

マッチングアプリで出会うためのコツは?

出会うまでの流れ

まずは、アカウントを作成

- プロフィール写真を選ぼう

- プロフィールの文章を作ろう

次に、気になる相手とマッチする!

- 検索機能で、気になる異性を見つけよう

- 気になる異性には「いいね!」を送ろう

最後に、気になる相手と初デート!

- 相手がOKしたらマッチング成立!

- メッセージでやりとりをしよう

- 実際に出かける約束をして初デート!

どのマッチングアプリでも

出会うまでの流れはほとんど同じ!

メッセージでのやりとりがデートへの鍵! 質問や通話に繋げることを意識しましょう。

プロフィールとメッセージの攻略で

デートに繋げよう

マッチングアプリで素敵な相手と出会うためには、誠実な気持ちを文章や写真から伝えるように意識することが大切。ここではマッチング率を上げてデートに繋げるために大事なプロフィールとメッセージについて徹底解説します!

- プロフィールや自己紹介文は作り込む

- プロフィー写真は顔がわかるものを設定する

- メッセージは誠実に対応する

- デートは自然に誘う

▼アプリごとのモテるプロフィールはこちら!

・ウィズでモテるプロフィールの作り方は?好印象の自己紹介文から写真の選び方までについて徹底解説!

・ペアーズのモテる写真について徹底解説!男女別NGな例も紹介!

・ゼクシィ縁結びのモテるプロフィールを解説!写真の設定方法も!

・オミアイのモテるプロフィールを解説!写真の設定方法も!

・ポイボーイでモテるプロフィールを作ろう!男女それぞれ実例付きで紹介

プロフィールの自己紹介文を作り込む

プロフィールをどう設定すればいいかわからない、自己紹介文に何を書けばいいのかわからないという人もいますよね。

プロフィールの中の自己紹介文で意識するポイントはこちら。

- 300文字前後で簡潔に書く。

- 顔文字や絵文字を適度に入れて柔らかい印象に。

自己紹介文で含めるべき内容はこちら。

- 職業

- 好きなこと/趣味

- 出会いの目的

職業は必須!相手に安心感を与えるために日頃の活動を伝えましょう。

好みや趣味は、人柄はもちろん話題作りに役立ちますね。

忘れがちなのが、出会いの目的。自己紹介できちんと盛り込むことで、

同じ目的を持つ相手とのマッチングが期待できます。

▼自己紹介文の例①

プロフィールを閲覧いただきありがとうございます!

東京在住で〇〇系企業で営業をしています。

リモートワークもあり、出会いがないので登録してみました。

将来を考えられる真剣な出会いを探しています。

休日は土日祝日です。

インドアでもアウトドアでも楽しい時間を一緒に共有できる関係を築ける人と出会いたいです。

最近はジムにハマってます。

お会いして雰囲気なども伝えられたらいいなと思います。

よろしくお願いします!!

誠実さをアピールして好印象を与えるのがポイントです。

▼自己紹介文の例②

また、以下のようにプラスαで食に関連することを入れるとデートに繋げやすいです。

食に関することを書くことで、初デートの行き先選びにも役立ちます。

「一緒に〇〇の新しいレストラン行きましょう!」という会話につながりやすいのでおすすめです。

詳細プロフィールは隠さず全部埋めて

マッチング率アップ!

詳細プロフィールとは「身長」「年齢」「居住地」「職業」

などアプリ側が設けている自己紹介項目のこと。

ニックネーム/年齢/血液型/兄弟姉妹/話せる言語/居住地/勤務地/出身地/学歴/職種/職業名/年収/身長/体型/結婚歴/子供の有無/結婚に対する意志/子供が欲しいか/家事・育児出会うまでの希望/初回デート費用/同居人/休日/お酒/タバコ/Facebook友達数

ウィズのように20以上の詳細プロフィールが設定されているアプリもあります。中には答えづらいものも、、。

しかし、マッチングアプリでモテたいなら全て埋めることが大事。

回答に困ることがあっても、盛りすぎず、正直に書くのがおすすめです。

身長/体型などの見た目を含め、デートすれば全てバレます!

デート代などもきちんと自分の予算を示しておくと負担がないですよ。

プロフィールの項目は全て埋めて真剣さをアピール。

盛り過ぎず正直に記載する方が好印象!

プロフィール写真は顔のわかるものを3枚以上設定

マッチングアプリで出会えるかは写真が9割と言われるほど大切!

写真撮影や写真選びはとくに慎重に行うようにしましょう。

失敗しないモテる写真のポイントは以下の5つ。

- 清潔感がある服装や背景

- 顔を隠しすぎはNG

- 他撮りの写真を選択する

- 趣味や特技の写真も載せる

- 3枚以上設定すること

自分の見た目や内面が伝わりやすい写真を選びましょう◎

いいねが100以上きた「モテるプロフィール写真」

マッチングアプリで実際に使用していいねが100以上きた

「モテるプロフィール写真」を紹介します。

▼ペアーズでいいねが100以上きたプロフィール写真(40代男性)

▼ウィズでいいねが100以上きたプロフィール画像

(20代男性)

顔がはっきりと写っていることや

背景や服装の清潔感があること

が好印象につながります◎

顔出しなしでいいねが100以上きた

「モテるプロフィール写真」

「どうしても顔を出すのが恥ずかしい」という方は

他撮りで自然体を意識した写真にし、雰囲気が伝わるよう工夫しましょう。

▼タップルでいいねが100以上きたプロフィール画像(20代女性)

▼マリッシュでいいねが100以上きたプロフィール画像(20代女性)

顔出しをしない人は、

自己紹介文を丁寧に書いてアピールするのがおすすめですよ。

メッセージは、誠実に対応する

マッチング後にメッセージが続かないと悩んでいる人も多いですよね。

メッセージにも続けるコツは6つ!

- 1通目はマッチング後すぐに送る

- 相手のプロフィール内容にふれる

- 質問をする

- 相手にいいねした理由を伝える

- 基本は敬語でやり取りをする

- 相手のペースに合わせてメッセージを送る

初めのメッセージはとくに大切

デートへ繋げやすくするためにも初めの印象は大切。

- 共通点を述べて誠実さをアピール!

- 質問して相手に興味があることをアピール!

どこが素敵だと思ったのか、どんな共通点があったのかわからない

文章は気持ちがこもっていないように感じます。

改善した文章を見てみましょう。

プロフィールをきちんと読んだこと、容姿だけでなく内面に興味があることがわかる文章だと好感度アップ!

好印象なメッセージ頻度とタイミング

基本は相手の女性に合わせるのが理想!

- 1日1往復

- お昼か19時〜23時の間

- 休日に多めに連絡を取る

<ポイント1>負担感のない連絡頻度

興味を持っていることを示しつつ、相手にプレッシャーを感じさせないちょうどいい頻度が1日1往復!

<ポイント2>相手を配慮したタイミング

お昼や19時~23時の間は相手が社会人でも

学生でも休憩時間か活動が終わる時間。連絡が取りやすい

です。

<ポイント3>頻度に差をつける

普段は忙しくて1往復しかできない連絡も

休日なら3往復くらいできるかも。

自分のことを考えてくれている気持ちが伝わり、嬉しく

思うでしょう。

デートは、メッセージの流れで自然に誘う

メッセージのやり取りがいい感じに続いているなら、思いきってデートに誘ってみましょう。

ここでは、OKされやすいデートの誘い方を解説します。

OKされるには、デートに誘うタイミングが重要です!

- メッセージのやり取りから1週間前後がおすすめ。

- 休日の過ごし方や好きな食べ物で話で盛り上がった時。

デートに誘うタイミングは、休日の過ごし方や好きな食べ物の話で盛り上がった時。

「お茶や食事をするのが目的」としたニュアンスで伝えるのがおすすめ◎

<ステップ①相手に質問する>

「休日は何をしてるんですか?」

「甘いもの好きですか?」

上記のように相手に質問して自然な流れで誘ってみてください。

そこから以下のように実際のデートに繋げていきましょう。

<ステップ②実際のデートに繋げる>

「代官山の美味しいカフェに行きましょう。」

「今週ランチでも行きましょう。」

「軽く飲みにでも行きましょう。」

▼アプリのメッセージのコツ&NGパターンを知りたい人はこちら

【マッチングアプリ別】

最初のおすすめメッセージ

最初のメッセージはアプリごとに工夫できます!

人気なアプリでの具体例を詳しく見ていきましょう。

Pairs

ペアーズでの初めのメッセージの送り方を見てみましょう。

趣味や興味をもとにしたコミュニティ機能から相手に

共有の話題を振れると好印象!

真剣に恋活するユーザーが多いので

慎重にメッセージを考えましょう。

Tapple

Tappleは「おでかけ機能」ですぐにデートしやすい

のが特徴のアプリ。

いきなりデートに誘うよりおでかけ機能の応募に声をかけてみると

いいでしょう。

気軽に会いたいユーザーが多いので

デートに繋げやすいメッセージが理想!

With

心理テストでマッチングできるウィズは内面を知ろうという姿勢を見せることが大切。

相手の考え方や人間性を深掘りするメッセージが好印象。

慎重に気の合う人を探すユーザーが

多いのでいきなりデートに誘うのはNG!

Omiai & YouBride

OmiaiとYouBrideは、どちらも婚活重視のアプリ!

誠実な印象のメッセージであることが重要。

メッセージの口調も他のアプリより少し堅めが好印象です。

生活感や価値観にも触れることができる話題だとより良いです!

初デートで好印象を与える

コツ・ポイント

初デートは今後に繋がるかを左右する大切な日。

- 自然な流れでデートの約束をする

- ベストなタイミングで会う

- 安心できるデート設定をする

- 会話を楽しむ

- スマートにお会計をする

- デート後にメッセージを送る

具体的にどのような行動を取ればいいかみていきましょう。

こんな誘い方は嬉しい!

自然にデートへ繋げよう

会話をしている流れでデートへ誘えるのが理想!

強引にデートにこじつけるのではなく、

趣味や好きな食べ物の話に関連

させて誘いましょう。

会うタイミングが大事!

どれくらいで会うのがベスト?

マッチング成立後約1~2週間程度が理想

の初デートタイミング!

ただし話の流れと相手によってベストは異なる!

1~2週間という期間が理想なのはお互いの興味が高い状態

で会えるから。

この期間が過ぎてしまうからと焦るのは

最もNG!

1週間過ぎたら、タイミングをみてデートに誘いましょう。

安心できるデート設定をしよう!

お昼時の3~4時間、落ち着いた雰囲気のカフェでデートがおすすめ。

デート設定の基準は以下です!

- 明るい時間に解散できるか

- 負担感のない長さなのか

- ゆっくり会話を楽しめる場所か

初回は長時間でのデートは避けましょう。

初デートでも楽しめる!

会話のポイント

意識してほしいのは一つの話題の中で3つ質問をすること。

質問はなるべく同じ話題から広げるようにしましょう。

なんの動物が好きなの?

犬かな!

そうなんだ!

他の動物は好き?

なんの動物が好きなの?

犬かな!

うんうん!

どの犬種が好きなの?

相手の興味のあるものについて

事前に調べておくと会話しやすくなります!

初デートのお会計はスマートに

女性がお財布を出す前に会計を済ませる

のが理想。

デートでのお会計を全額または多めに出して欲しい

と考える女性は60%以上。

しかし、対等な関係を望んで割り勘がいいという女性もいます。

全額会計を済ませた上で

女性が払いたいと言ってきたら受け取り

ましょう。

初デートの後はお礼メッセージを送ろう

デートの後はお礼のメッセージを送りましょう!

- 楽しかったことを先に送る

- また会いたいことを続ける

デートの終わりから数時間後または翌日の午前中

に送るのがベストタイミング!

デートの印象が新鮮なうちに感謝の

気持ちがもらえると嬉しいですよね。

マッチングアプリの実態は?

マッチングアプリ利用者632人の利用目的はこちら!

マッチングアプリを使う目的で多いのは何?

| 恋人探し(結婚意識せず) | 220人 |

| 恋人探し(結婚前提) | 191人 |

| 異性の友達探し | 58人 |

| 遊び相手探し(ワンナイトなど) | 54人 |

| 結婚相手探し | 45人 |

| 暇つぶし | 39人 |

| ハッキリした目的なし | 24人 |

| その他 | 1人 |

「恋人探し」は全体の65%を超えています。

ワンナイトや暇つぶし、ハッキリした目的がないなど

ライトな関係を求める人が少ないのは出会い系との違いです。

利用者のほとんどが、結婚まではいかなくても真剣で長い付き合いを探しています。

恋活、婚活をしたい人はマッチングアプリを使うのがおすすめ!

マッチングアプリは安全?トラブルはある?

マッチングアプリは運営側も積極的に安全対策を行っています。

トラブルについて632人の回答を集めたところ、約7割がトラブル経験なし、約3割がトラブル経験ありでした。

| トラブルの有無 | 回答者 |

|---|---|

| なかった | 410名 |

| あった | 222名 |

実際に利用者が体験したトラブルについてもまとめました。

| トラブルの種類 | 回答者 |

|---|---|

| 写真が加工されていて本人と違った | 80人 |

| ヤリモクだった | 63人 |

| すっぽかしやドタキャンをされた | 42人 |

| メッセージで不快な言葉を言われた | 39人 |

| 宗教やビジネスの勧誘をされた | 24人 |

| 既婚者だった | 13人 |

| 恋人がいる人だった | 10人 |

| 年齢の詐称 | 6人 |

| 職業の詐称 | 2人 |

- ビデオチャットで事前に顔を合わせて確認

- デート場所を自分で提案

アンケート結果をみると、「会ったら微妙、写真と全然違った」という不満が見られます。

まずは、写真だけで過度に期待しすぎないことが重要。

一部のユーザーからは、「お昼であってもホテルに誘われた」という報告があります。

デート場所を自分で提案するなどの対策が有効です。

待ち合わせは公共の場所にする、近くにホテルのないお店を選ぶなどで対処しましょう。

大体のトラブルは事前準備で防ぐことができます。事前に相手とビデオで顔を合わせておき、デートはお昼に公共の場所に決めておくのが最適です◎

マッチングアプリ側は安全対策を行なっている

マッチングアプリの急速な普及に伴い安全対策が強化されてきました。

マッチングアプリの安全を守るため、以下のようにな機能があります!

- 本人確認の強化

- 監視体制の整備

- 通報機能やブロック機能

中には通報機能やブロック機能も付いているものも◎

利用規約や安全対策をしっかり確認し、安心してよい出会いを見つけましょう!

マッチングアプリ初心者が気をつけるポイント

- 業者に気をつける

- ヤリモク・美人局に注意

- 未成年と関係をもたないように気を付ける

本来の目的から逸脱したユーザーも紛れ込んでいる可能性もあることを頭に入れておくことが重要。

簡単に信用せず、慎重に段階を踏みましょう。

恋人ができやすいアプリを知りたい!

アンケート結果から、利用者が多かった上位5位のアプリでは付き合えた割合は以下のようになりました。

| アプリ | 付き合えた人の割合 |

|---|---|

| Omiai | 65% |

| with | 61% |

| ペアーズ | 53% |

| タップル | 53% |

| Tinder | 48% |

付き合えた人の割合はTinder以外全てのアプリで過半数を超える結果に。

同じように、利用者の多い5つのアプリで結婚をした人の割合を見てみると以下のようになりました。

| アプリ | 結婚した人の割合 |

|---|---|

| Omiai | 18% |

| with | 13% |

| ペアーズ | 14% |

| タップル | 11% |

| Tinder | 8% |

結婚につながる恋愛はどのアプリでもハードルが高いですね。

マッチングアプリおすすめの

よくある質問!

ここからは、マッチングアプリに関するよくある質問について解説します。

- 通報機能の使い方は?

- マッチングアプリの初心者マークって何?

- マッチングアプリの退会方法は?

- 身バレしたくない場合は?

通報機能の使い方は?

ほとんどのアプリで簡単に使用できます!

- 通報したい相手のプロフィールをタップ

- プロフィールの「・・・」をタップ

- 「通報する」をタップ

相手が退会してしまっても3ヶ月以内なら問題を報告できるアプリが

多いので逃げられる恐れもありません。

通報が相手にバレることはないので

安心してくださいね。

マッチングアプリの初心者マークって何?

With、Tapple、Pairsなどの主要アプリではアプリに登録した直後から一定の期間、ユーザーにマークを付与しています。

初心者マークがある期間は検索に引っかかりやすくなっているため

マッチングしやすい!

| アプリ | 表示期間 |

|---|---|

| With | 1週間 |

| Tapple | 2週間 |

| Pairs | 3日 |

マッチングアプリの退会方法は?

ほとんどのアプリでマイページから簡単に退会できます。

退会手続きを行うと、これまでのマッチングやメッセージ履歴などのデータは全て削除されるので注意。

- マイページへ行こう

- 「設定」か「お問い合わせ」をタップ

- 退会理由を選択しよう

- 「退会手続きを続ける」をタップ

- 「退会する」をタップ

退会をしただけでは、有料プランの自動更新は

解除されていません。

必ず、自動更新解除を忘れずに!

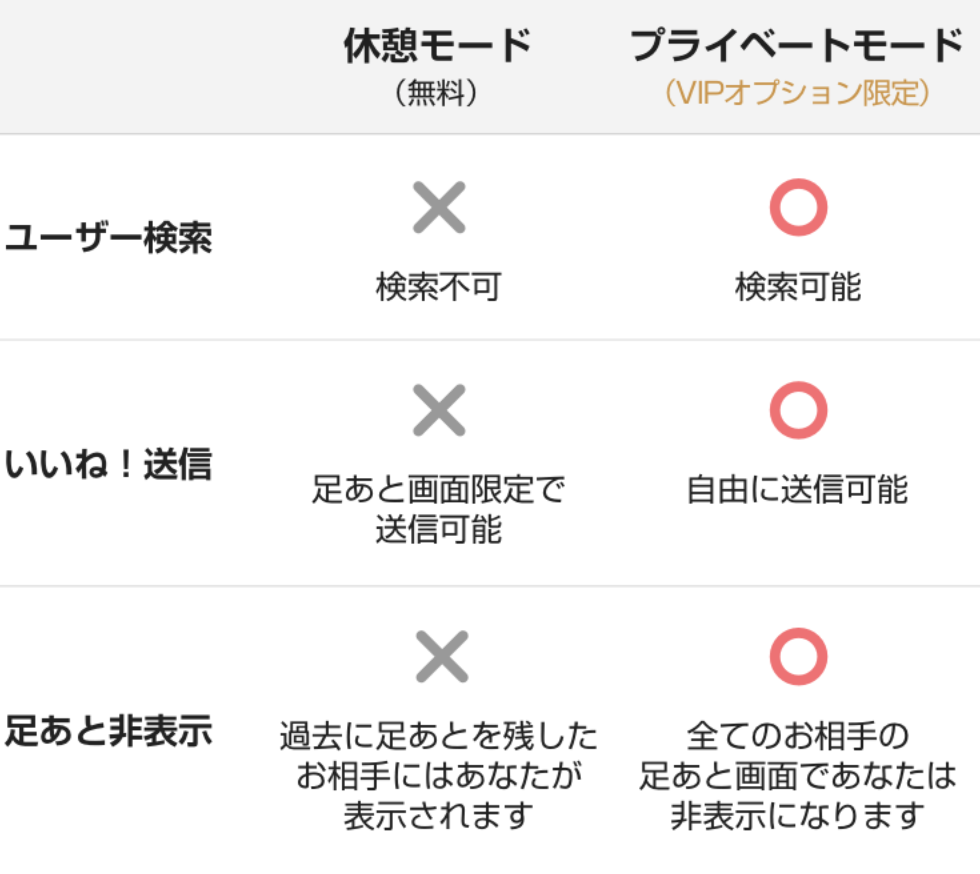

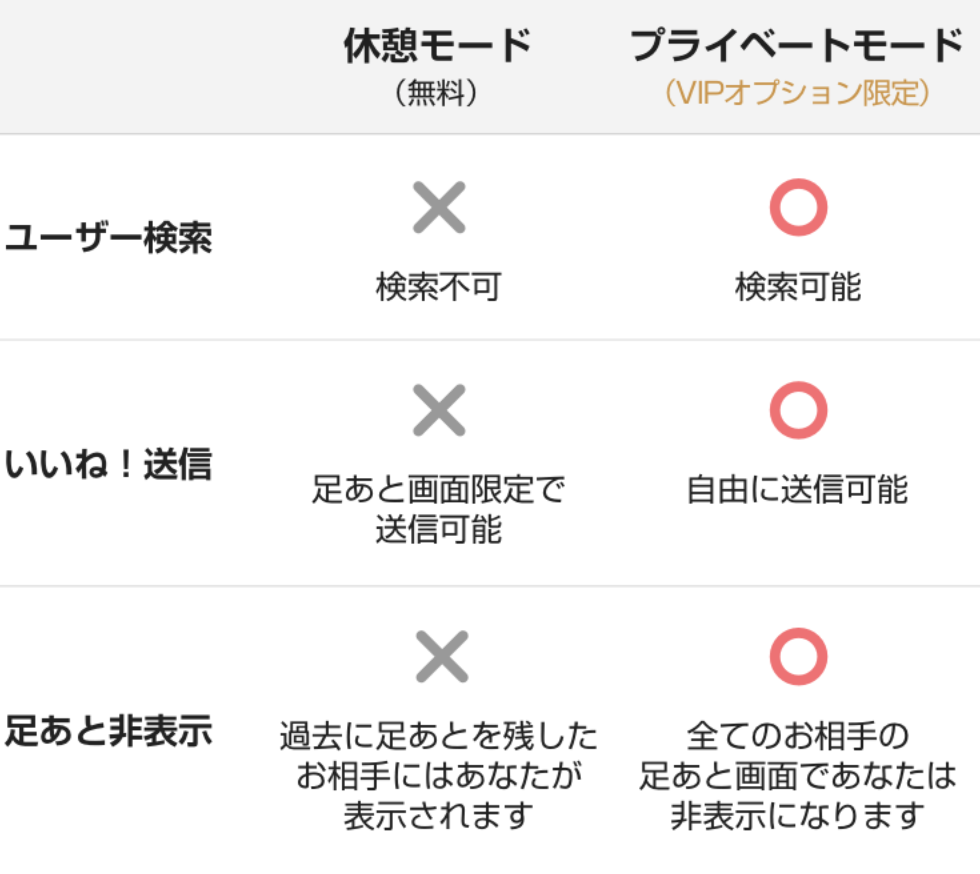

身バレしたくない場合は?

身バレしたくない人は身バレ防止機能を使用できます。

身バレ防止機能とは自分が「いいね」した相手にしかプロフィールが表示されない機能のこと。

| アプリ名 | 料金 | 身バレ防止 機能 |

|---|---|---|

| With | 1ヶ月プラン2,900円〜 | VIP オプション |

| Pairs | 1ヶ月プラン2,560円〜 | プライベートモード |

| Tapple | 買い切り1,220円(退会まで有効) | プライベートモード |

| Omiai | 無料 | 「非公開」 設定 |

主要アプリの身バレ防止機能が上記です!

登録時にFacebookと連携すると

Facebook上の友達が表示されなくなるので身バレ防止に!

Withの身バレ防止機能の使い方

契約したら各種設定からプライベートモードの設定で「ON」を設定すれば身バレ防止機能がつきます。

ウィズでは無料で使用できる休憩モードがあります。

休憩モードとの違いはこちら!

Pairsの身バレ防止機能の使い方

月額の追加料金でプライベートモードに申し込むと使用できるよう

になります。登録方法は簡単です!

<ステップ1>マイページの有料会員をタップ

<ステップ2>詳しい情報をみるをタップ

<ステップ3>案内に沿って手続きする

使いたい月額プランをタップして申し込む。

<ステップ4>プライベートモードを設定する

もう一度マイページから

「プライベートモード設定」をタップしてON/OFを切り替えましょう。

ペアーズではプライベートモード以外でプロフィール非表示機能はない!

どうしても身バレしたくない人は申し込みましょう。

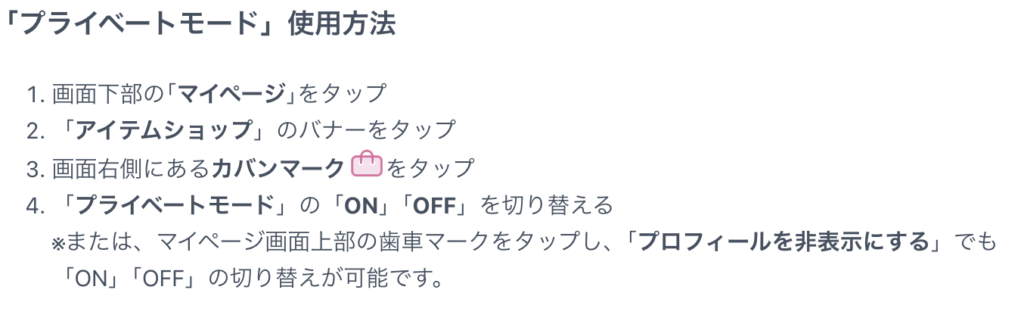

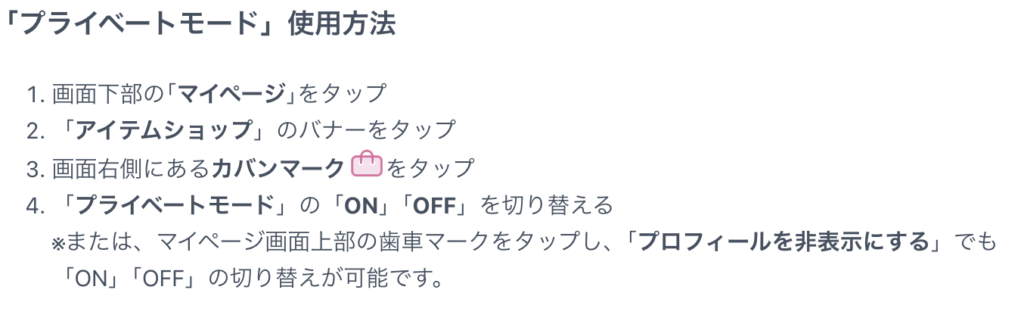

Tappleの身バレ防止機能の使い方

Tappleの身バレ防止機能は買い切り型

のプライベートモード。

1,220円で一度購入すれば退会まで使用できます。

マイページのアイテムショップで購入して使用を開始しましょう!

Omiaiの身バレ防止機能の使い方

マイページから「非公開設定にする」で無料で

身バレ防止!

- マイページから「各種設定」をタップ

- 「プロフィールの公開設定」をタップ

- 公開を制限したい項目を「非公開」に

- 「設定する」をタップ

Omiaiなら無料で試せるので身バレが気になる方はにはおすすめ。

マッチングアプリを使って

楽しく出会おう

この記事では、以下の基準でおすすめのマッチングアプリをランキング形式で紹介しました。

- 初心者でも使いやすいこと!

- 男女とも出会いやすいこと!

- 安全に使えるアプリなこと!

マッチングアプリを使う際に大切なことは、自分に合ったアプリを選ぶこと。

自分に合ったマッチングアプリを選ぶことができれば、どんな人でも素敵な出会いができます!

少しでも気になっているアプリがあれば、とりあえず登録して覗いてみてくださいね!